Types of industrial pumps

Industrial pumps are designed for harsh or heavy-duty applications. They convey a range of material

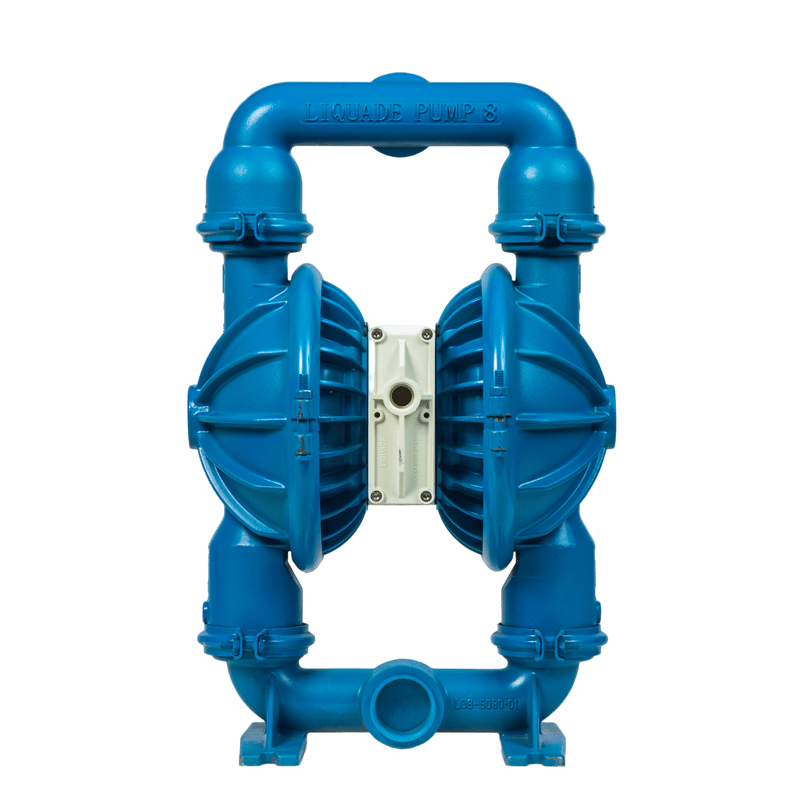

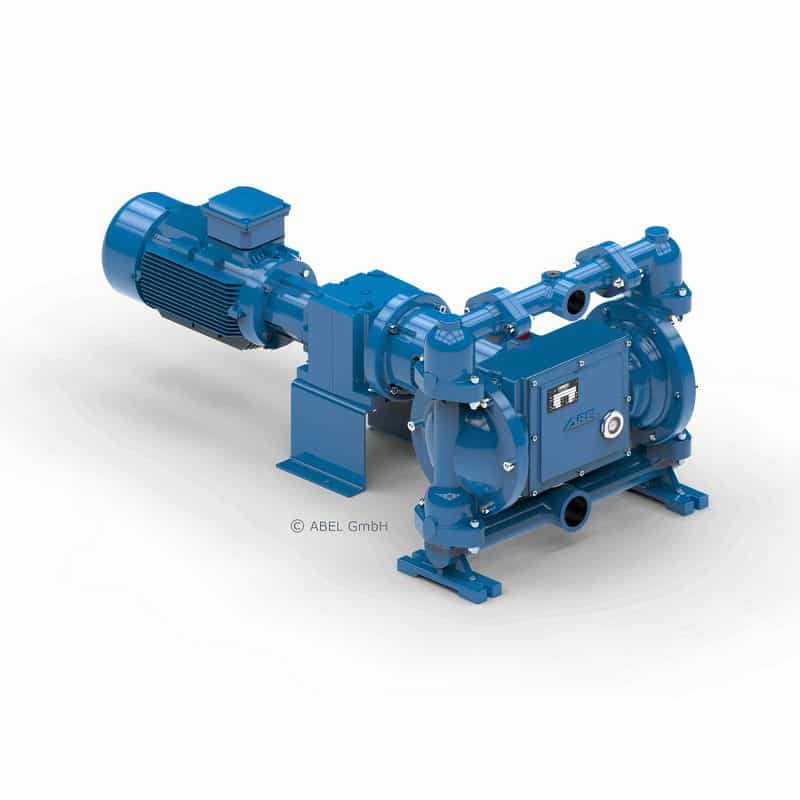

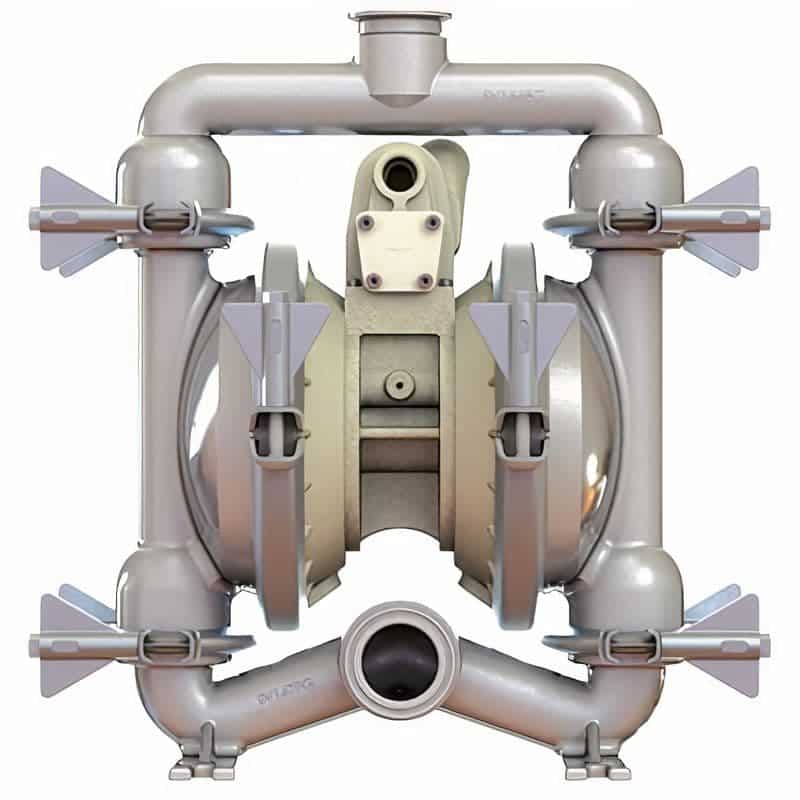

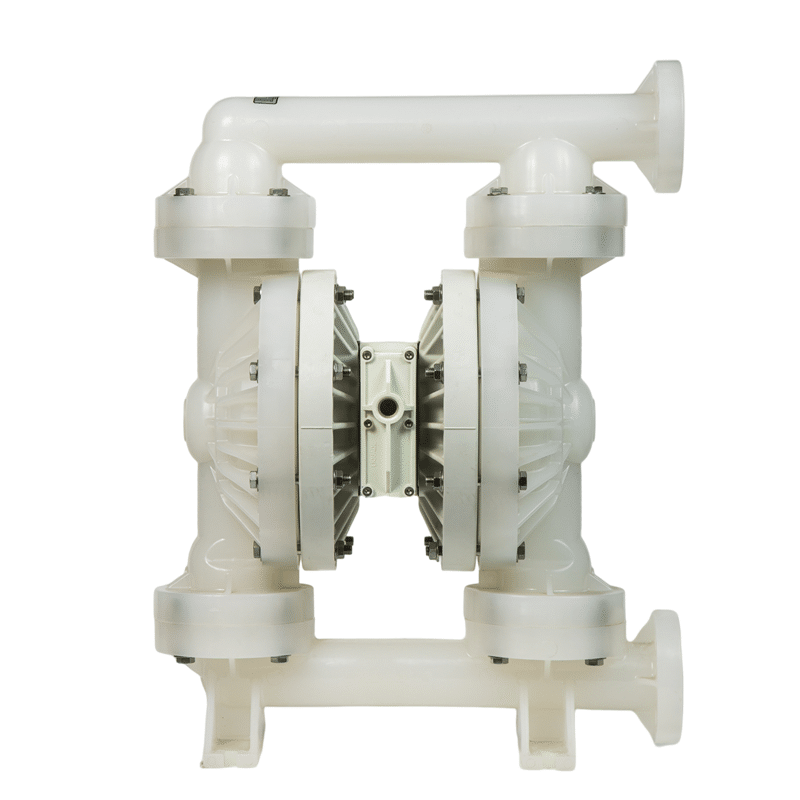

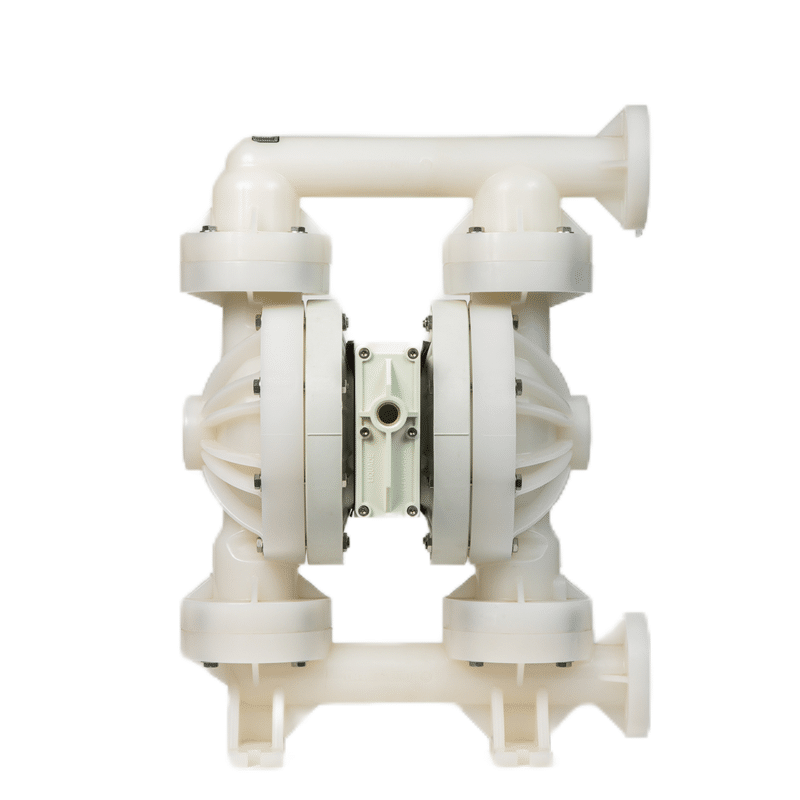

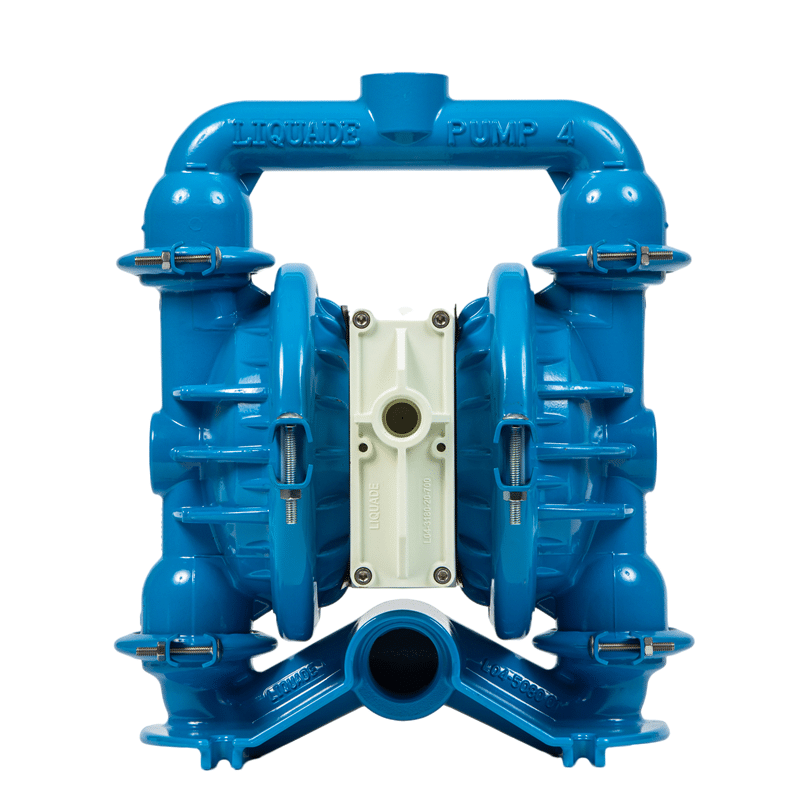

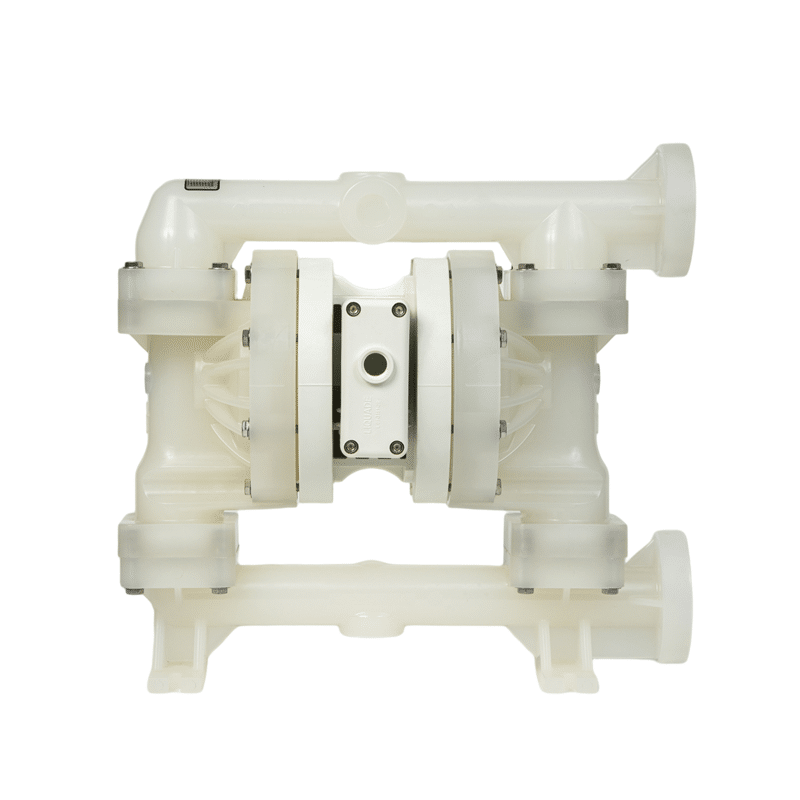

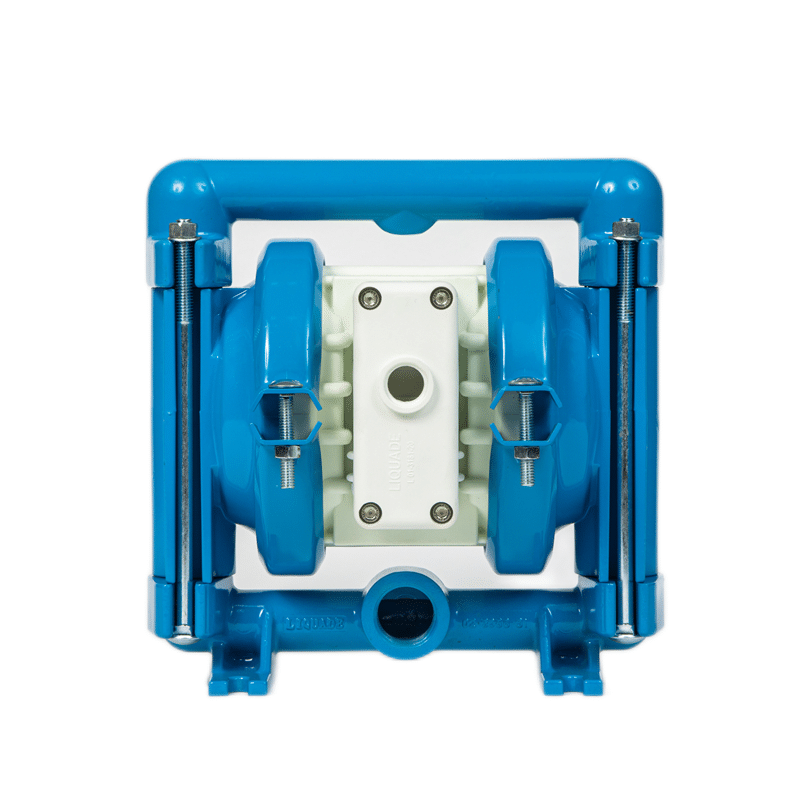

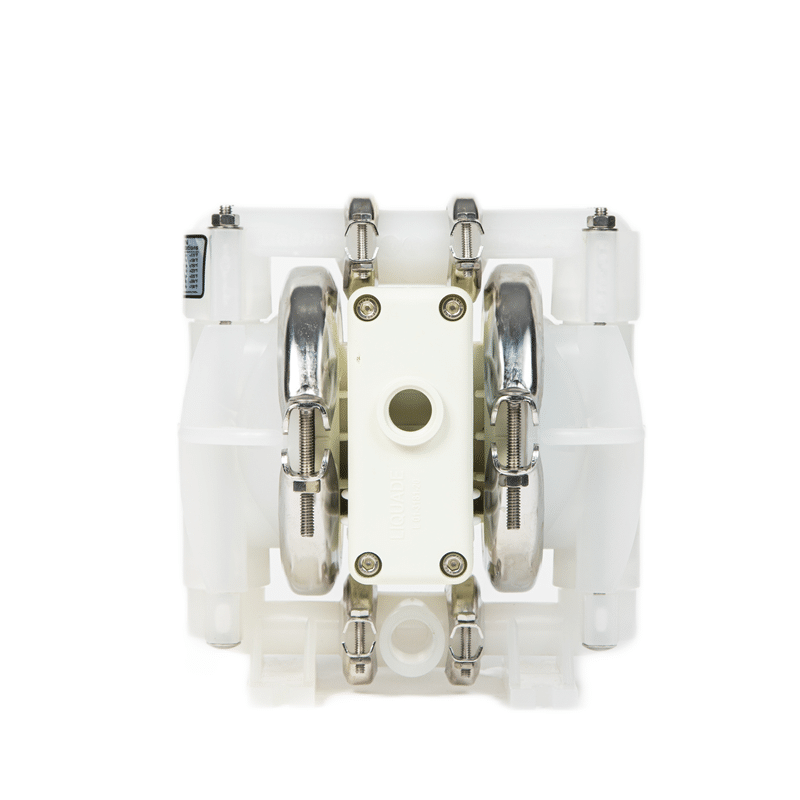

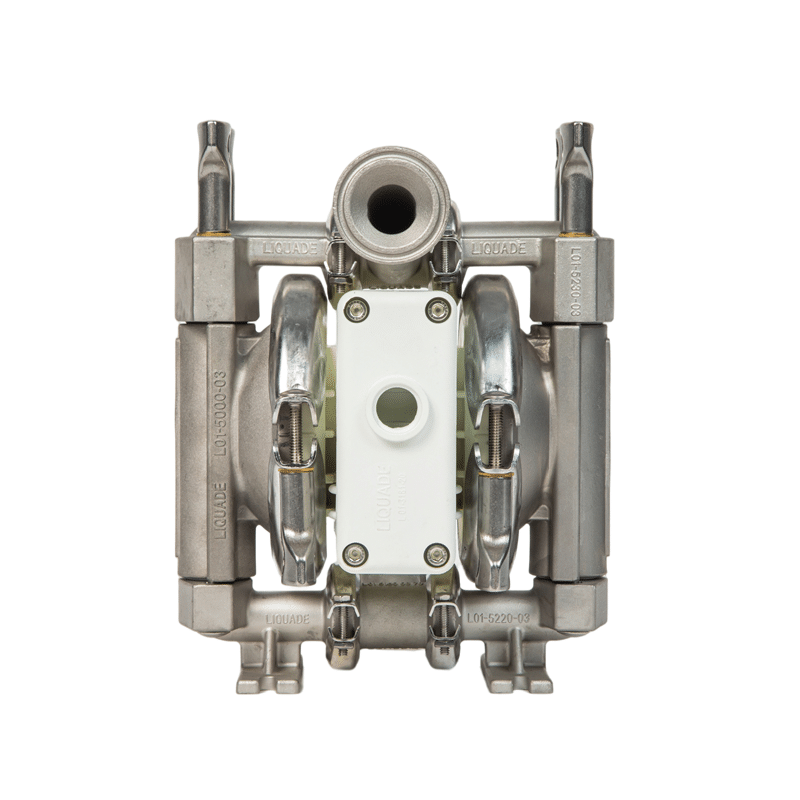

Diaphragm pumps are positive displacement pumps commonly used in wet commercial pumping applications. Air diaphragm pumps operate on compressed air and transport grout, solvents and other high viscosity liquids.

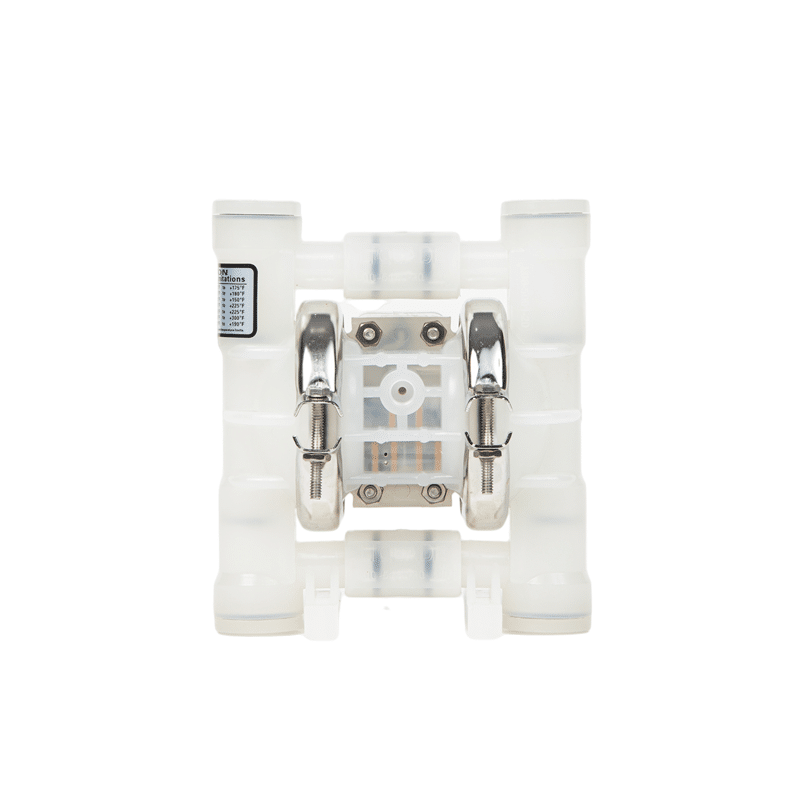

Pneumatic diaphragm pump has four kinds of materials: engineering plastics, aluminum alloy, stainless steel, cast iron. Air operated diaphragm pump according to different liquid medium respectively using nitrile rubber, neoprene rubber, fluorine rubber, polytetrafluoroethylene, poly forty-six ethylene.

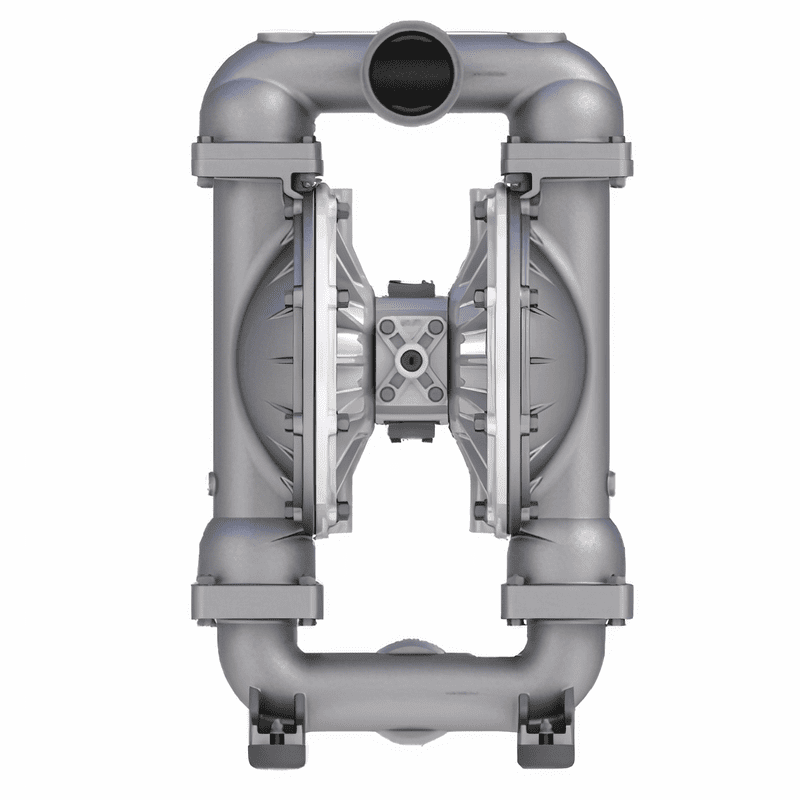

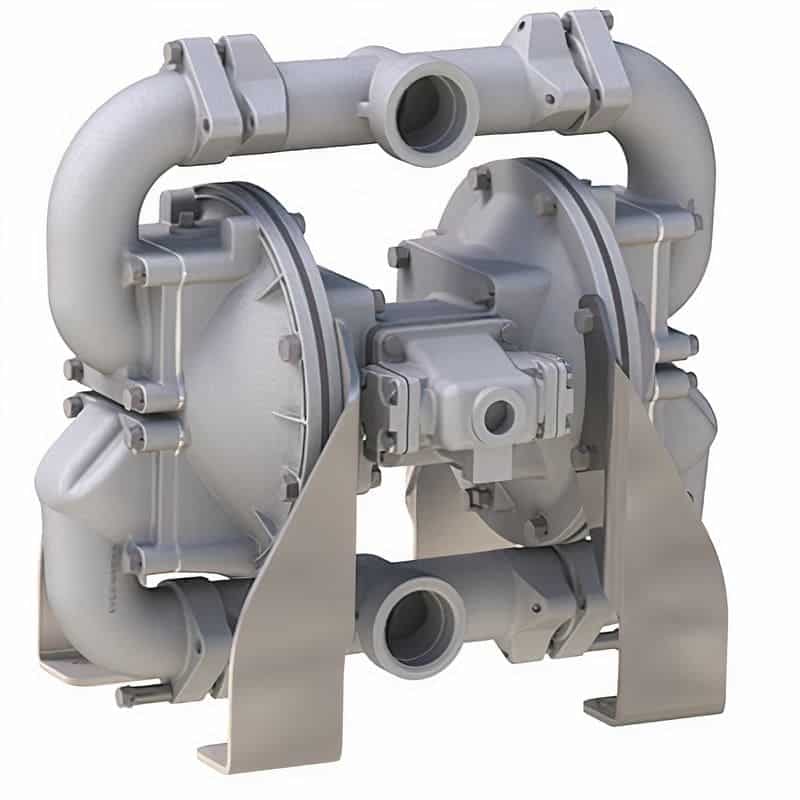

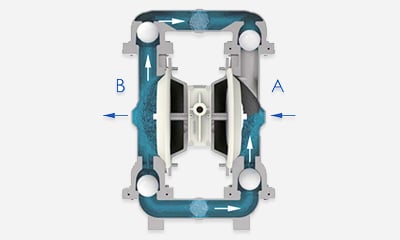

The working principle of double diaphragm pump is a positive displacement reciprocating pump that relies on the air compressor to input compressed air into the distribution valve of the diaphragm pump to drive the link shaft in the middle body of the diaphragm pump to drive the diaphragm pump diaphragm in the medium chamber of the diaphragm pump body to do transverse stretching to achieve the role of self-priming fluid. In the two symmetrical working chamber of the pump, each equipped with a piece of elastic diaphragm, the link rod will form a body of two diaphragm, compressed air from the pump inlet joint into the distribution valve, to promote the diaphragm in the two working chamber, driving the two diaphragm joint synchronous movement. At the same time, the gas in the other working chamber is discharged from the pump behind the diaphragm. Pneumatic diaphragm pump by the flow structure and liquid flow structure of two major components, through the two sides of the diaphragm completely isolated.

Air pressure only needs to be greater than two kilograms per square centimeter to work. At 5 to 8 kg working pressure, the high pressure gas in the valve chamber drives the connecting rod shaft to reciprocate left and right through the air flow dredging system, and the consumed low pressure gas is discharged quickly through the exhaust port. Under the alternating action of high and low pressure gas on both sides, the connecting rod shaft drives the diaphragm on both sides to move around, so that the air pressure in the volumetric cavity on both sides changes alternately, so as to realize the continuous suction and discharge of liquid.

Pneumatic diaphragm pump is also called air operated diaphragm pump, double diaphragm pump or aodd pump. It is a new type of conveying machinery, using compressed air as power source, for all kinds of corrosive liquids, with particles of liquid, high viscosity, volatile, flammable, highly toxic liquid, can be suction.

With compressed air as the power, the diaphragm reciprocating deformation caused by volume change of the positive displacement pump, its working principle is like the plunger pump.

Industrial pumps are designed for harsh or heavy-duty applications. They convey a range of material

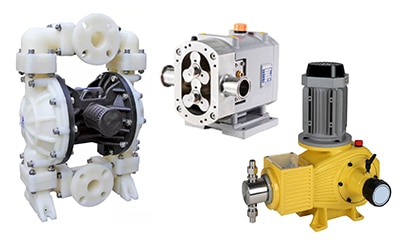

What is positive displacement pump? Positive displacement (PD) pumps move fluid by repeatedly closing a

Pump is a mechanical device used to transfer different fluids from one position to another.

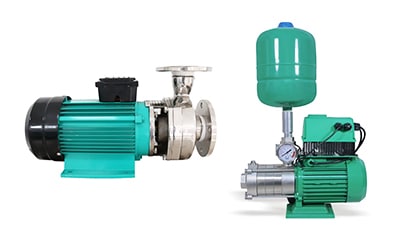

What is a booster pump? Booster pumps increase low water pressure and flow. It provides

What is chemical dosing system? Chemical dosing system is a complete set of equipment with

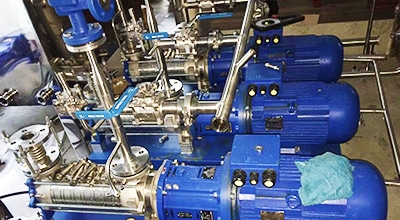

What is a screw pump? Screw pump is a part of the dry compressed gas

What Is A Diaphragm Pump? Air operated double diaphragm pump, also known as an AODD

What is a dosing pump? Dosing pump, also known as dose pump, metering pump, is

‘HAOSH‘ is a major dosing metering pump brand of Shanghai GL Environmental Technology Co., Ltd. Also as a pump category super market, we supply diaphragm pumps, chemical pumps, water pumps, screw pumps, etc. Since founded in 2007, HAOSH brand has for more than 100 countries of the world’s more than 3000 clients with high quality pumps.