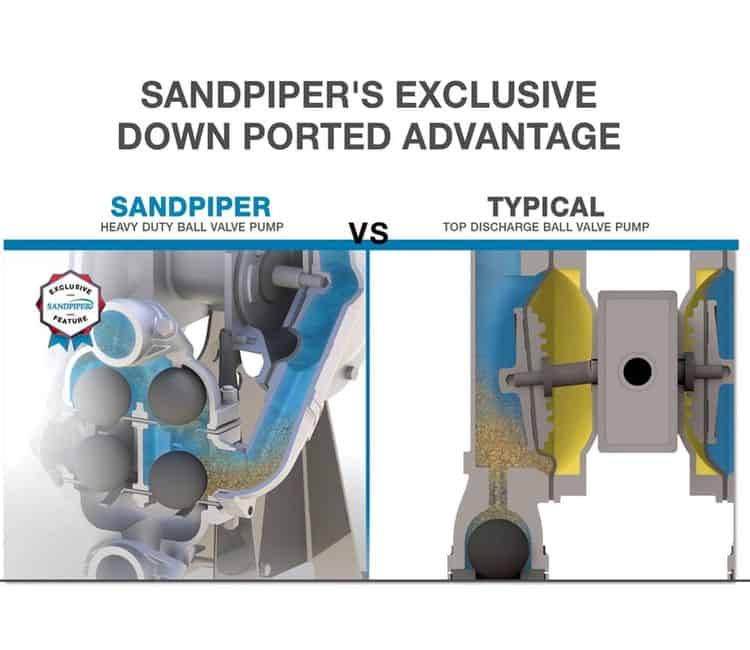

The extended wear package of Sandpiper Heavy-Duty Ball Pumps includes heavier duty plunger bushings and actuator pins, diaphragm wear pads, and weighted check valve balls. This package can help to extend the life of the pump in demanding applications. The HDB3 and HDB4 are available in top- and down-ported options for optimized performance. The down-ported design also helps to prevent air entrainment, which can lead to cavitation and pump damage.

| Port Size | 3″ 150# ANSI Flange 4″ 150# ANSI Flange |

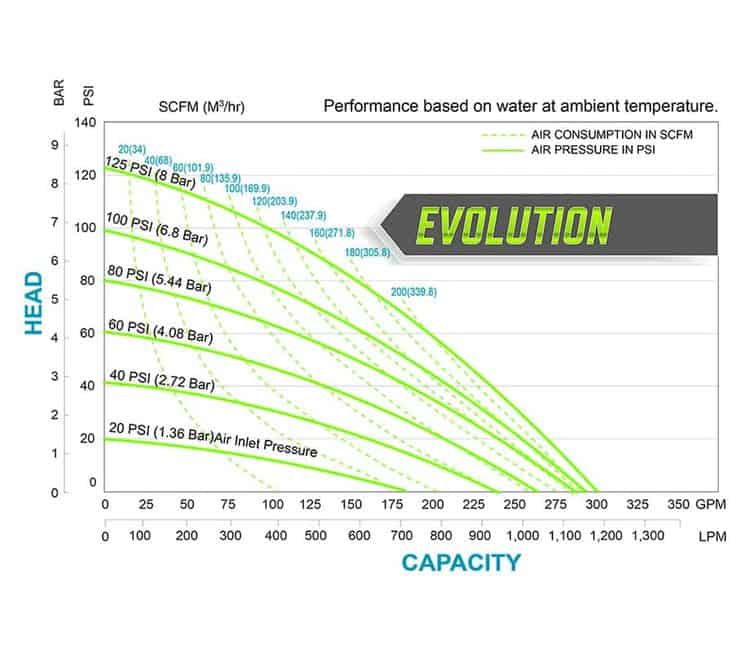

| Capacity | 0 to 300 gpm (1136 lpm) |

| Air Distribution Valve | No-lube, no-stall design |

| Solids-Handling | Up to .875″ (22.2 mm) |

| Heads Up To | 125 psi or 289 ft. of water (8.6 bar or 88 meters) |

| Displacement/Stroke | 2.0 gallons (7.6 liters) |

| Max Operating Pressure | 125 psi (8.6 bar) |

| Shipping Weight Cast Iron Stainless Steel |

460 lbs (207 kg) 480 lbs (216 kg) |

‘HAOSH‘ is a major dosing metering pump brand of Shanghai GL Environmental Technology Co., Ltd. Also as a pump category super market, we supply diaphragm pumps, chemical pumps, water pumps, screw pumps, etc. Since founded in 2007, HAOSH brand has for more than 100 countries of the world’s more than 3000 clients with high quality pumps.