Dosing metering pump working principle

What is a dosing pump? Dosing pump, also known as dose pump, metering pump, is

Chemical dosing pumps dispense liquid at a precise rate. Also known as metering pumps, quantitative pumps or proportional pumps, they can handle harsh and dangerous liquids such as alkali, mud and corrosives. Dosing pump is a fluid conveying machinery, its outstanding feature is to maintain a constant flow independent of the discharge pressure. Metering pump can be used to complete the function of conveying, metering and regulation at the same time, thus simplifying the production process. Widely used in petrochemical, pharmaceutical, food and other industrial fields.

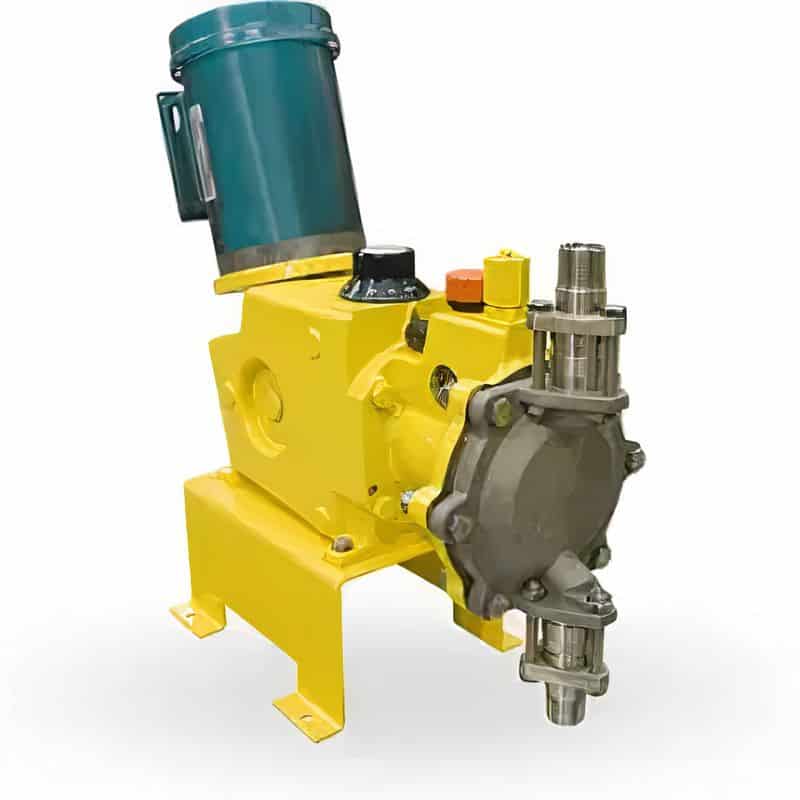

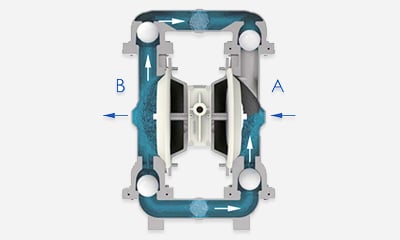

So how does the dosing pump work? The motor of the dosing pump drives the worm through the coupling and decelerates the worm gear to make the spindle and the eccentric rotate, and the eccentric drives the sliding adjustment seat of the bow connecting rod to reciprocate. When the plunger moved back to the dead point, the pump cavity gradually formed a vacuum, the suction valve opened, suction liquid; As the plunger moves forward to the dead center, the suction valve closes, the discharge valve opens, and the liquid is discharged as the plunger moves further. The reciprocating line of the pump also works to form a continuous pressure, quantitative discharge liquid.

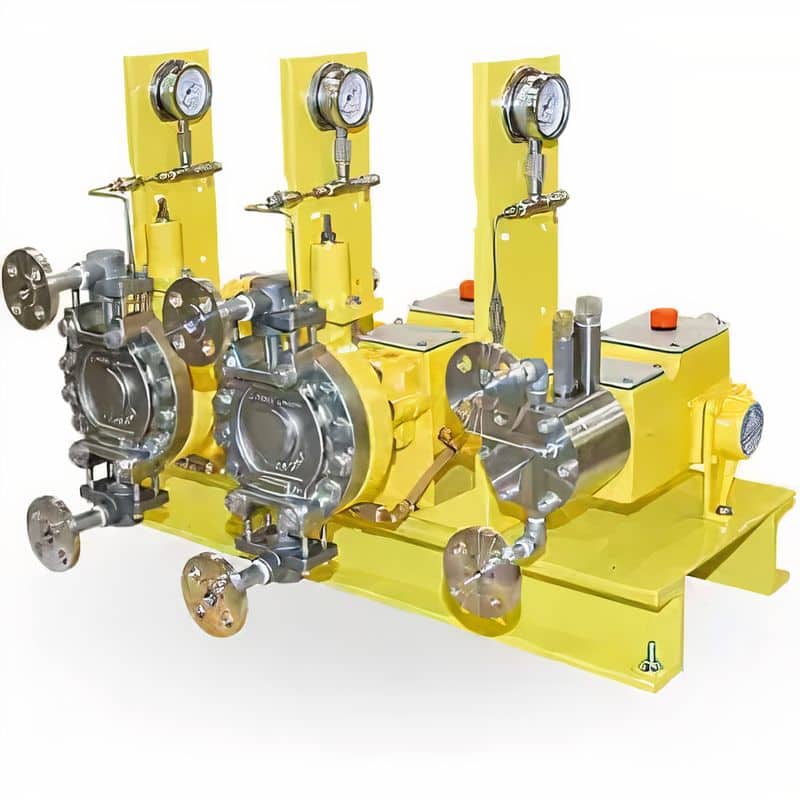

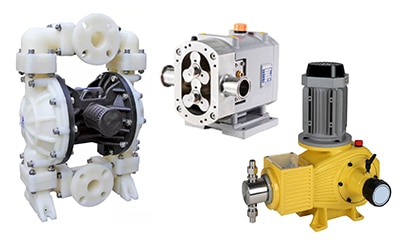

Metering pump, also known as dosing pump, quantitative pump or proportional pump, as the name implies metering pump is a kind of machinery can measure the delivery of liquid, it is a kind of can meet all kinds of strict process needs, the flow can be in the range of 0-* stepless adjustment, used to transport liquid a special volume pump. Metering pump according to the flow part can be divided into plunger, piston, mechanical diaphragm, hydraulic diaphragm type; According to the driving mode can be divided into: motor drive, electromagnetic drive; According to the working mode: reciprocating, rotary, gear type.

Metering pump is mainly composed of three parts: power drive (motor), fluid transport (transmission frame parts) and adjustment control (pump head parts). The power drive device drives the fluid conveying diaphragm to achieve reciprocating movement through the mechanical linkage system: the diaphragm (piston) will be transported in the first half of the stroke of the fluid suction and in the second half of the fluid discharge pump head; Therefore, fluid throughput can be controlled by changing the reciprocating movement frequency or the stroke length of each reciprocating movement. The precise machining accuracy ensures the precise measurement of the conveying medium at each pump.

4 conventional metering pump types are designed for different pressures, chemicals and applications. They vary by pumping action and mechanism:

In many industries and applications, the use frequency of electromagnetic diaphragm metering pump and mechanical diaphragm metering pump will be relatively high, small flow generally with the former, large flow will use the latter.

Diaphragm metering pump due to the use of hydraulic oil evenly drive diaphragm, overcome the mechanical direct drive pump diaphragm force is too concentrated disadvantage, improve the diaphragm life and working pressure upper limit.

You can tell us what you need by submitting the form on the website, and then we have special personnel to connect with you and confirm the technical parameters, delivery and logistics information, we support the trade of the vast majority of countries in the world.

Suitable for high pressure, low pressure, strong (weak) corrosion and high measurement accuracy.

For example, additives used in the petroleum industry and natural gas extraction; Chemical industry used for adding proportional chemical media; For environmental protection on the industrial water treatment pump; Dosing pump for purifying water treatment in boiler of thermal power plant, etc.

Dosing metering pump is a part of dosing system, dosing system is through the online detection system, automatic dosing system to control the chemical dose of the circulating water system, to effectively prevent the circulating water system often appear scaling, corrosion, biological mud and bacteria and algae problems.

Main components include:

Chemical vessel or tank – holds the product to be dosed.

Pump-Various materials and sizes; includes inlet, suction, and dosing tubes.

Injector-a one-way valve into which the chemical is injected into the product; overcomes the pressure in the piping and allows the chemical to enter the liquid flow.

Bottom valve-a one-way valve attached to the suction line; placed inside the product drum to keep the pump in the starting position.

Dosing line – rigid or reinforced hose; can be PE, PVC, or stainless steel for high pressure use.

Control system – ensures accuracy; opens and closes at specific times. Can be a simple flow switch or timer, to a variety of sensors for SCADA central control systems, and can be integrated into a larger system.

What is a dosing pump? Dosing pump, also known as dose pump, metering pump, is

What Is A Diaphragm Pump? Air operated double diaphragm pump, also known as an AODD

Did you know that only 3% of the water on earth is fresh? As the

What is chemical dosing system? Chemical dosing system is a complete set of equipment with

Pump is a mechanical device used to transfer different fluids from one position to another.

What is positive displacement pump? Positive displacement (PD) pumps move fluid by repeatedly closing a

Industrial pumps are designed for harsh or heavy-duty applications. They convey a range of material

Solenoid dosing pump is a form of displacement pump that uses a diaphragm and solenoid

‘HAOSH‘ is a major dosing metering pump brand of Shanghai GL Environmental Technology Co., Ltd. Also as a pump category super market, we supply diaphragm pumps, chemical pumps, water pumps, screw pumps, etc. Since founded in 2007, HAOSH brand has for more than 100 countries of the world’s more than 3000 clients with high quality pumps.