Diaphragm metering pump with special flexible diaphragm replace piston design processing, under the action of a driving mechanism to realize reciprocating motion, complete the suction and discharge process. Electric diaphragm pump due to the isolation of the diaphragm in the structure of the measurement of fluid and drive lubrication mechanism between the isolation.

Diaphragm metering pump with special flexible diaphragm replace piston design processing, under the action of a driving mechanism to realize reciprocating motion, complete the suction and discharge process. Electric diaphragm pump due to the isolation of the diaphragm in the structure of the measurement of fluid and drive lubrication mechanism between the isolation. High-tech structure design and selection of new materials have greatly improve the service life of the diaphragm, coupled with excellent corrosion resistance properties of composite materials, diaphragm metering pump has now become the main pump fluid metering application type.

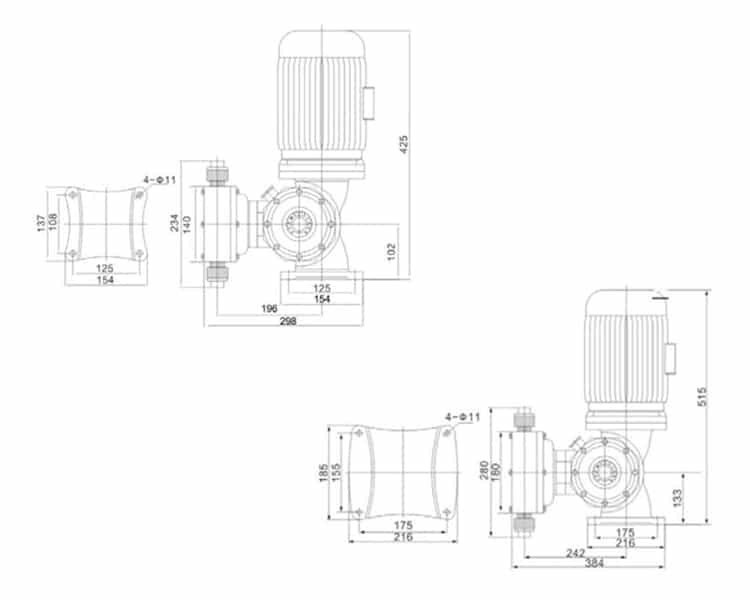

The main parts of mechanical diaphragm metering pump are made of precision casting and numerical control processing.The structural design of the liquid receiving end ensures that the pump will not leak during operation. The material of the driving parts is sturdy and durable.

Due to the compact design,The equipment is easy to operate.Liquid flow can be easily adjusted by flow adjusting knob, and it is convenient for installation and maintenance.

Features:

What is a diaphragm metering pump?

Diaphragm metering pump uses a specially designed and processed flexible diaphragm to replace the piston, and realizes reciprocating movement under the action of the driving mechanism, completing the suction – discharge process. Due to the isolation function of the diaphragm, the separation between the measured fluid and the driving lubrication mechanism is really realized in the structure. High-tech structural design and the selection of new materials has greatly improved the service life of the diaphragm, coupled with the excellent corrosion resistance of composite materials, diaphragm metering pump has become the main pump in the application of fluid metering.

‘HAOSH‘ is a major dosing metering pump brand of Shanghai GL Environmental Technology Co., Ltd. Also as a pump category super market, we supply diaphragm pumps, chemical pumps, water pumps, screw pumps, etc. Since founded in 2007, HAOSH brand has for more than 100 countries of the world’s more than 3000 clients with high quality pumps.