Water pump procurement guide

Water pumps are extremely versatile tools that can solve a variety of problems and make

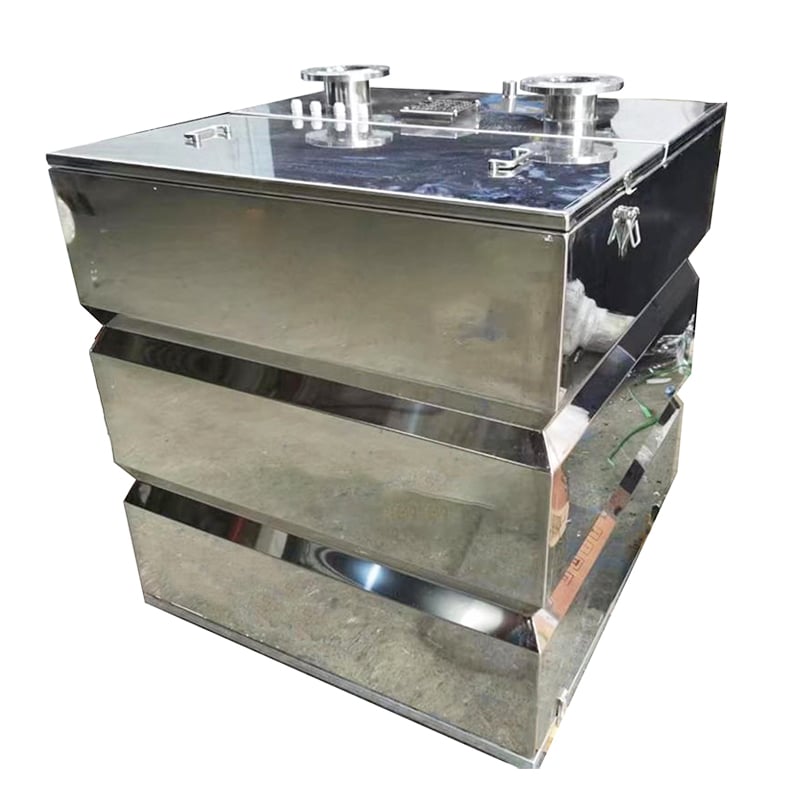

Vertical multistage pump is a kind of mechanical equipment that can transport from tap water to industrial liquid. Standard vertical motor and quick loading mechanical seal, easy to change. The flow parts of the pump are made of stainless steel (304\316), which can be used in mildly corrosive media.

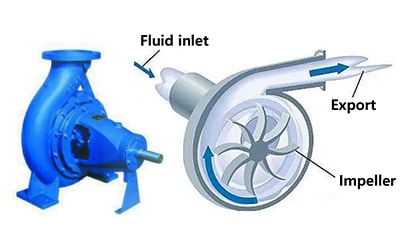

When the motor driven shaft of high-speed rotating impeller, filled with liquid under the action of centrifugal force in the impeller, the impeller center around the perimeter of the blade passage between the left to the impeller, because the liquid is the role of the blade, the pressure and velocity increase at the same time, after conducting shell of flow channel and the lead time level of impeller, this is principle of successive flow with all of the impeller and guide shell, Further increases the pressure energy of the liquid. After stacking each impeller step by step, a certain head is obtained.

Submersible sewage pump can sewage long fiber, bag, belt, grass, cloth and other substances torn, cut off, and then smooth discharge, especially suitable for conveying liquid containing hard solid, fiber and especially dirty, sticky, slippery liquid.

Unique impeller structure and new mechanical seal can effectively transport solids and long fibers. Impeller compared with the traditional impeller, the coal pump impeller using single channel or double channel form, it is like a cross-section size of the same elbow, has a very good flow.

A. Remove the upper shell of the pump to expose the upper impeller,

B. Turn the impeller by hand to see if it is flexible

C. Pull the impeller along the axial direction of the pump to observe the total channeling of the impeller seven times (general QJ pump 4-6 mm)

D. Install the coupling device and the motor to be integrated so that the motor shaft head and the pump shaft head are tight without allowing gaps.

E. See impeller up and down channeling clearance, should be in the middle of the total channeling (allowable deviation ±0.5 mm).

F. When the deviation is greater than 0.5 mm, adjust the impeller to the middle position with the adjusting gasket.

G. Then drill the top screw hole of the coupling device and tighten the top screw to install the upper shell.

H. Once again with a pry rod to dial the coupling should be flexible rotation for the assembly. Then install the filter screen and wire groove box.

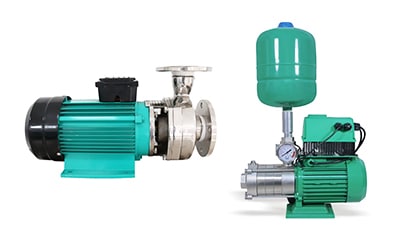

General flow control of booster pump can’t use, with general self-priming pump can, if installed on the head, when solar need water, open the other leading to pressure solar, or choose to use manual switch to booster pump can also be mandatory start, just remember to turn off after the expiration of the pump.

Water pumps are extremely versatile tools that can solve a variety of problems and make

Industrial pumps are designed for harsh or heavy-duty applications. They convey a range of material

What is a centrifugal pump? A centrifugal pump is a mechanical device that moves fluid

Pump is a mechanical device used to transfer different fluids from one position to another.

What is a booster pump? Booster pumps increase low water pressure and flow. It provides

Although it is common to hear the terminology used interchangeably, there are actually some very

Solar is more than just an environmentally friendly power source – it’s convenient, low-maintenance, and

What is a dosing pump? Dosing pump, also known as dose pump, metering pump, is

‘HAOSH‘ is a major dosing metering pump brand of Shanghai GL Environmental Technology Co., Ltd. Also as a pump category super market, we supply diaphragm pumps, chemical pumps, water pumps, screw pumps, etc. Since founded in 2007, HAOSH brand has for more than 100 countries of the world’s more than 3000 clients with high quality pumps.