Types of industrial pumps

Industrial pumps are designed for harsh or heavy-duty applications. They convey a range of material

AOBL acid resistant pumps can handle a variety of liquids and are ideal for chemical transfer, many suitable for continuous duty and high flow applications. They are available in a variety of horsepower sizes, inlet/outlet sizes, seal materials, and wet materials. Some corrosion resistant pumps have pump housings with seal flushing ports to eliminate contamination of seals and seat elastomers. Pedestal models feature a motor mounted on top of a riser, while the close coupled pump is designed for easy installation and maintenance.

We have a range of mechanically sealed chemical pumps, as well as our new range of magnetically driven (magnetic drive) acid pumps designed to be efficient, yet economically priced with consideration.

All wet parts of the pump, such as the impeller, are made of advanced plastics and thermoplastics for maximum corrosion resistance. Pumps are internally lined with plastic as well as superior chemical resistance characteristics.

Types of chemicals that can be pumped by our pumps includes but is not limited to the following:

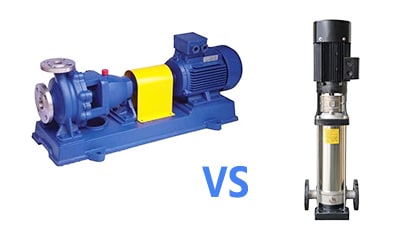

Acid pumps are classified by function: self-priming acid pump, magnetic drive pump, and vertical acid pump. Resistance to acid and alkali pump is a kind of special material pump, suitable for – 20 ℃ ~ + 120 ℃ temperature under the conditions of transportation of all kinds of corrosive medium, the over-current parts are all made of plastic alloy (ptfe and fep, and other materials) with reasonable formula, mold, processing and become, acid proof pump with the advantages of a variety of plastic, has a strong corrosion performance, and has the advantages of high mechanical strength, no aging, no toxin decomposition, is the ideal equipment for conveying all kinds of strong and weak acid.

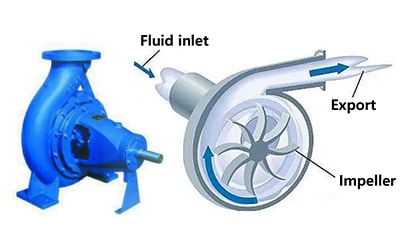

The suction line and pump must be filled with liquid before starting the chemical pump. After the pump is opened, the impeller rotates at a high speed, and the liquid rotates with the blade. Under the action of centrifugal force, it flies off the impeller and ejects outward. The speed of liquid injection in the diffusion chamber of the pump shell gradually slows down and the pressure gradually increases. Water outlet, water outlet pipe. At this point, at the center of the blade, the liquid is thrown around so that there is neither air nor liquid forming a vacuum low-pressure area. The liquid in the liquid pool flows into the pump through the suction pipe under the action of atmospheric pressure on the pool surface. It is continuously sucked out of the reservoir and continuously discharged from the discharge line.

1, the first confirmed good conveying liquid must choose the material of chemical pump and seal material, or due to the pump body or sealing material could not bear corrosion of liquid, will cause a delay of chemical production and unnecessary economic losses, so in the selection process for the chemical pump users must inform the delivery name, medium temperature and medium to choose the appropriate chemical pump.

2, followed by the need for chemical pump flow and head, head must be confirmed, in the selection of chemical pump procurement personnel had better understand the height of the chemical pump, distance, elbow valve number and accurate inform chemical pump manufacturers.

3, it is important to note, finally must confirm a good chemical pump transmission medium density, viscosity, and particle impurities, if the weight is too much based on the original chemical pump motor selection more motor power, viscosity is too large to consider choosing low rotating speed of the chemical pump products or choose air driven products.

Industrial pumps are designed for harsh or heavy-duty applications. They convey a range of material

What is a centrifugal pump? A centrifugal pump is a mechanical device that moves fluid

Pump is a mechanical device used to transfer different fluids from one position to another.

Did you know that only 3% of the water on earth is fresh? As the

Centrifugal pumps can be found in many industrial applications. They offer excellent operating efficiency and

What is mag drive pump? Mag drive pump is a seal-less chemical process pump that

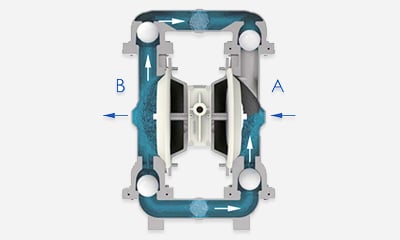

What Is A Diaphragm Pump? Air operated double diaphragm pump, also known as an AODD

What is a dosing pump? Dosing pump, also known as dose pump, metering pump, is

‘HAOSH‘ is a major dosing metering pump brand of Shanghai GL Environmental Technology Co., Ltd. Also as a pump category super market, we supply diaphragm pumps, chemical pumps, water pumps, screw pumps, etc. Since founded in 2007, HAOSH brand has for more than 100 countries of the world’s more than 3000 clients with high quality pumps.