Sulfuric acid resistant centrifugal chemical pump can easily handle sulfuric acid, hydrochloric acid, nitric acid, chromic acid, hydrofluoric acid and other acid and alkali liquids.

Sulfuric Acid Resistant Centrifugal Chemical Pump

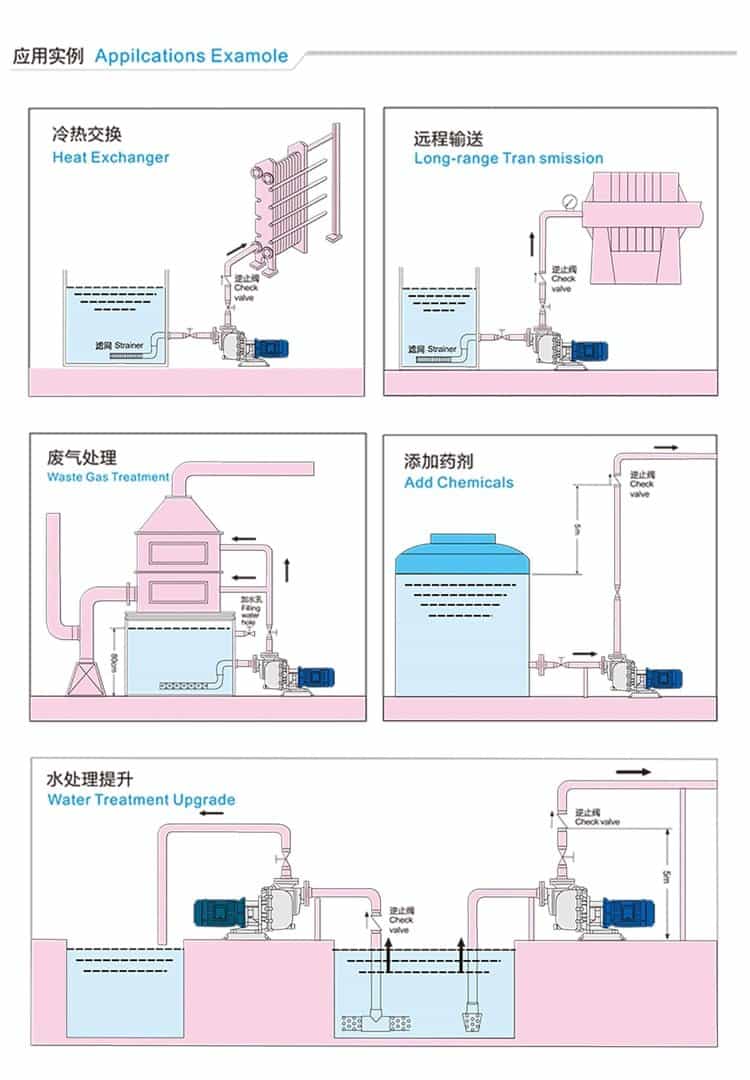

AOBL chemical pump can easily handle sulfuric acid, hydrochloric acid, nitric acid, chromic acid, hydrofluoric acid and other acid and alkali liquids. Suitable for pumping all kinds of corrosive medium chemical liquid and water. Widely used in electroplating, PCB, sewage engineering, metal surface treatment, waste gas treatment, etc.

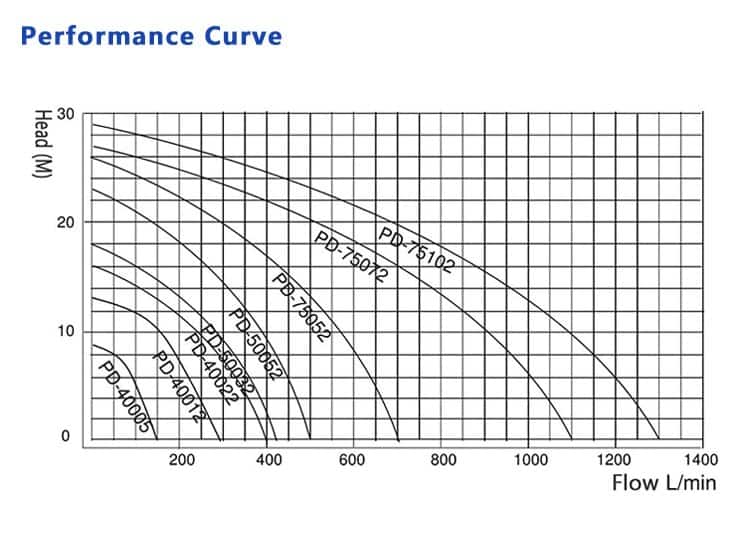

| Model | Thread connection | Maximum output | Standard output | Specific gravity | Motor | ||||

| Inlet | Outlet | Flow | Head | Flow | Head | Power(L/Min) | Voltage | ||

| (mm) | (mm) | (L/min) | (m) | (L/min) | (m) | (W) | (V) | ||

| MPH-400 | G1½ | G1½ | 280 | 12.5 | 150 | 8.5 | <1.3 | 0.37 | 380 |

| MPH-401 | G1½ | G1½ | 330 | 18 | 200 | 12 | <1.3 | 0.75 | 380 |

| MPH-422 | G2 | G1½ | 400 | 23 | 200 | 18.5 | <1.3 | 1.5 | 380 |

| MPH-423 | G2 | G1½ | 500 | 24 | 300 | 20.5 | <1.3 | 2.2 | 380 |

| MPH-550 | G2½ | G2 | 600 | 25 | 400 | 22 | <1.3 | 3.0 | 380 |

| MPH-650 | G2½ | G2 | 870 | 30 | 500 | 26 | <1.3 | 3.7 | 380 |

| MPH-850 | G3 | G2½ | 1100 | 25 | 800 | 18 | <1.3 | 5.5 | 380 |

| MPH-860 | G3 | G2½ | 1400 | 28 | 1100 | 21 | <1.3 | 7.5 | 380 |

1. Different chemical solutions mixed together will cause reaction and even heat to damage the pump. Don’t pump different chemical solutions with the same pump.

2. Chemicals may cause serious injury. Keep away from dangerous area.

3. Before operating, please check the discharge and suction line and valvesrst. Make sure valves are all in correct position, then start. During operation, check discharge usually.

4. Incorrect operation, for example, valves closed, incompatible material and dry running may cause dangerous. Especially dry running, it will cause heat as well as vapor, even some chemical decomposes hydrogen and explode.

5. Start the pump and check the discharge from the outlet. If it is too low, unplug the pump immediately, and check the pipeline if there is any block..

6. The pump can be equipped with explosive-proof and pressure-proof motor.

Chemical pump is the national joint design of energy saving pump, pump performance, technical requirements, according to the international standard ISO2858 provided by the performance and size of the design, can be divided into stainless steel chemical pump, plastic chemical pump, fluorine plastic chemical pump, electric chemical pump, pneumatic chemical pump.Advantages: the whole series of hydraulic performance layout is reasonable, the user can choose a wide range, “open back” structure, easy maintenance, efficiency and suction reach the international advanced level.

What is an acid resistant pump?

Acid and alkali resistant pump is a special material of pump. Widely used in electroplating, PCB, environmental protection equipment and other industries. Acid proof pump product is suitable for – 20 ℃ ~ + 120 ℃ temperature under the conditions of transportation of all kinds of corrosive medium, the over-current parts are all made of plastic alloy (ptfe and fep, and other materials) with reasonable formula, mold, processing and become, acid proof pump with the advantages of a variety of plastic, has a strong corrosion performance, and has high mechanical strength, No aging, no toxin decomposition and other advantages, is the ideal equipment for conveying all kinds of strong and weak acid.

‘HAOSH‘ is a major dosing metering pump brand of Shanghai GL Environmental Technology Co., Ltd. Also as a pump category super market, we supply diaphragm pumps, chemical pumps, water pumps, screw pumps, etc. Since founded in 2007, HAOSH brand has for more than 100 countries of the world’s more than 3000 clients with high quality pumps.