RV single eccentric screw pump is an American standard designed for small flow liquid. Special structure pump designed for body transfer system. Absorption capacity is strong, up to 7-8m, even at very low speed, flow stability. Usually used as dosing pump for measurement.

Mono Single Eccentric Screw Pump

RV screw pump is an American standard designed for small flow liquid

Special structure pump designed for body transfer system. It has a general structure

In addition to its working characteristics, it has the following advantages:

● Axial dimensions are small, 1/3-1/2 shorter than conventional pumps, and pumps tend to be miniaturized.

Temperature impact small, low working torque.

● Absorption capacity is strong, up to 7-8m, even at very low speed, flow stability.

Usually used as dosing pump for measurement.

● Low energy consumption, suitable for the miniature pump, even 40W motor can work normally.

● RV product models of 0.4, 0.8 and 1.5 are expressed as at 0MPa.

At 400r/min, the flow rate is 0.4 l /min, 0.8 l /min. 1.5l, the latter number is 3, which can produce 1.6-1.8mpa work stress.

● Similarly, the previous Numbers of 3.2, 6.2 and 12.2 are shown at 0MPa and 400r/min

The flow rate is 3 liters per minute. 6 liters, 12 liters, the latter number 2 is 2

The stage pump can produce 1.01-1.2mpa working pressure.

| Model | DN1 | DN2 | H1 | H2 | L | L1 | L2 | S | S1 |

| RV0.4.3 | G3/4″ | G1/2″ | 30 | 80 | 700 | 80 | 540 | 285 | 255 |

| RV0.8.3 | G3/4″ | G3/4″ | 30 | 80 | 700 | 80 | 540 | 285 | 255 |

| RV1.5.3 | G1″ | G1″ | 30 | 80 | 700 | 80 | 540 | 285 | 255 |

| RV3.2 | G1″ | G1″ | 30 | 80 | 700 | 80 | 540 | 285 | 255 |

| RV6.2 | G1″ | G1″ | 30 | 80 | 700 | 80 | 540 | 285 | 255 |

| RV12.2 | G11/4″ | G11/4″ | 30 | 80 | 700 | 80 | 540 | 285 | 255 |

What is a eccentric screw pump?

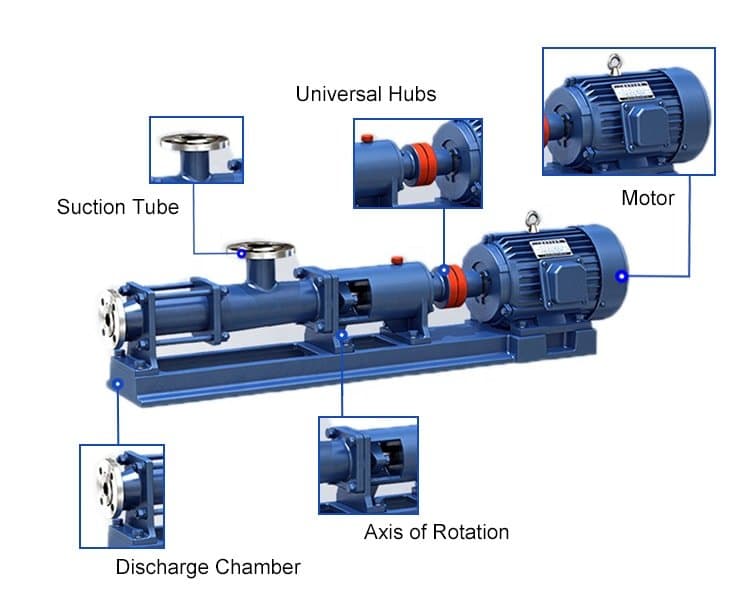

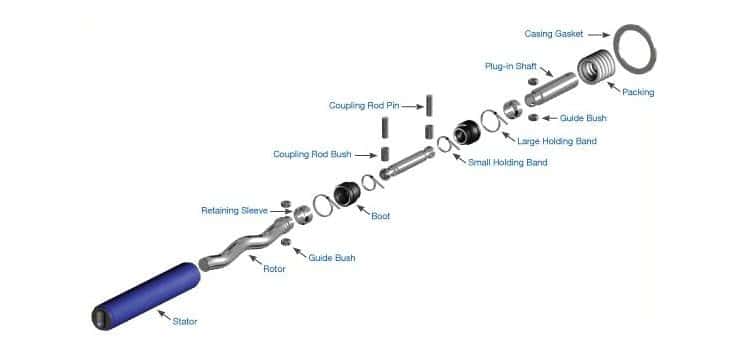

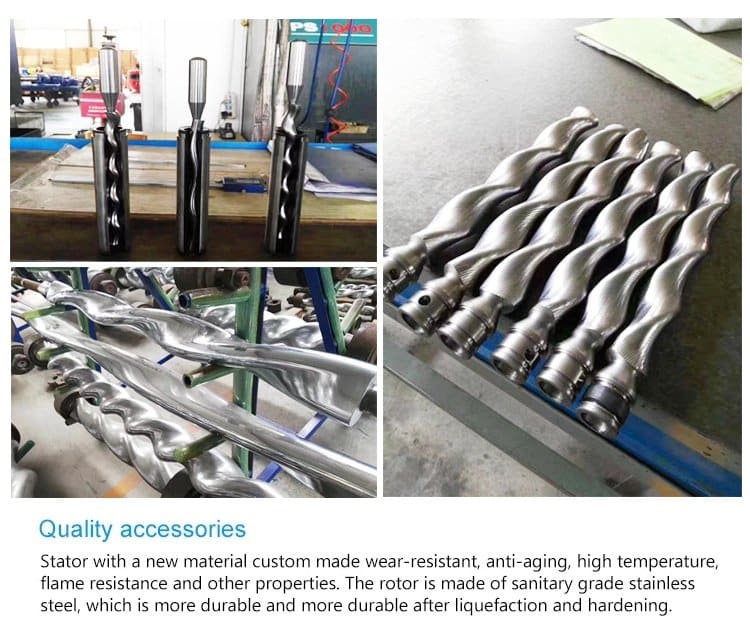

Eccentric screw pump belongs to the rotor positive displacement pump, which relies on the screw and bushing meshing each other in the suction chamber and discharge chamber to produce volume changes to transport liquid. It is an internal meshing closed screw pump, the main working parts by a double head spiral cavity bushing (stator) and in the stator cavity meshing with a single head spiral screw (rotor) composition. When the input shaft through the universal joint drive making planets revolving around the center of the stator, rotor stator, rotor, vice is continuous mesh form sealed cavity, the seal chamber volume invariably uniform axial movement, the medium from the suction end of deputy to the stator, rotor pressure side, the suction medium sealed cavity through the stator without stirring and destruction.

‘HAOSH‘ is a major dosing metering pump brand of Shanghai GL Environmental Technology Co., Ltd. Also as a pump category super market, we supply diaphragm pumps, chemical pumps, water pumps, screw pumps, etc. Since founded in 2007, HAOSH brand has for more than 100 countries of the world’s more than 3000 clients with high quality pumps.