Alkali acid HCL magnetic liquid pump can easily handle sulfuric acid, hydrochloric acid, nitric acid, chromic acid, hydrofluoric acid and other acid and alkali liquids.

Alkali Acid HCL Magnetic Liquid Pump

The transition parts are made of reinforced polypropylene plastics, pump shafts, bearings and end rings are made of highly corrosion resistant materials.Such as ceramic, filling tetrachloroethylene, carbon, ensure safe transport chemical fluid. Mostly, with no shaft seal design, the bottom of the early solve the traditional mechanical shaft seal pump inevitable run, run, drip, leakage ect.it is to optimize the design of the structure with glass fiber reinforced plastic parts, impeller and injection molding are used within the magnetic rotor, reduce the volume of the system components, greatly improving the pump effect of the

main components of a modular, can quickly remove and check, maintenance is easy.

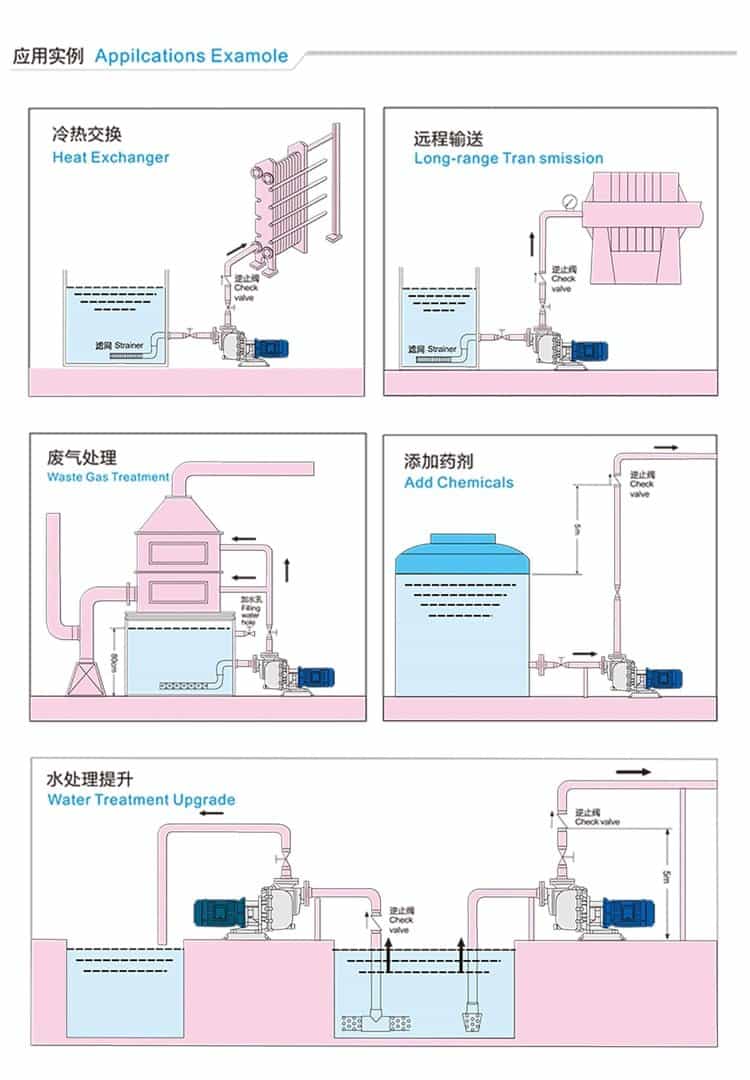

1. Different chemical solutions mixed together will cause reaction and even heat to damage the pump. Don’t pump different chemical solutions with the same pump.

2. Chemicals may cause serious injury. Keep away from dangerous area.

3. Before operating, please check the discharge and suction line and valvesrst. Make sure valves are all in correct position, then start. During operation, check discharge usually.

4. Incorrect operation, for example, valves closed, incompatible material and dry running may cause dangerous. Especially dry running, it will cause heat as well as vapor, even some chemical decomposes hydrogen and explode.

5. Start the pump and check the discharge from the outlet. If it is too low, unplug the pump immediately, and check the pipeline if there is any block..

6. The pump can be equipped with explosive-proof and pressure-proof motor.

Magnetic drive circulation pump is a full-sealeed pump, for motor connecting shaft and impeller

are separately equipped with magnetic materials, they attract each other and coupled. It’s

unnecessary to fit with traditional shaft seal. The rotation of motor drives impeller to rotate through the attraction between driving magnet and driven magnet. Our magnetic drive circulation pump is generally designed for no shaft seal, completely avoids defects of pollution after corrosion caused by liquid leakage,which exists in traditional mechanical shaftscal pump. It is the optimum liquid transport pump on the industrial equipments.

‘HAOSH‘ is a major dosing metering pump brand of Shanghai GL Environmental Technology Co., Ltd. Also as a pump category super market, we supply diaphragm pumps, chemical pumps, water pumps, screw pumps, etc. Since founded in 2007, HAOSH brand has for more than 100 countries of the world’s more than 3000 clients with high quality pumps.