What is positive displacement pump?

Positive displacement (PD) pumps move fluid by repeatedly closing a fixed volume and moving it mechanically through the system. Simply put, positive displacement pump is a pump that uses the change in volume within the pump cylinder to move fluid. The pumping action is cyclic and can be driven by pistons, screws, gears, rollers, diaphragms or vanes.

Positive displacement pump working principle

There are many types of positive displacement pump designs, but most can be divided into two categories: reciprocating and rotary.

Reciprocating positive displacement pumps

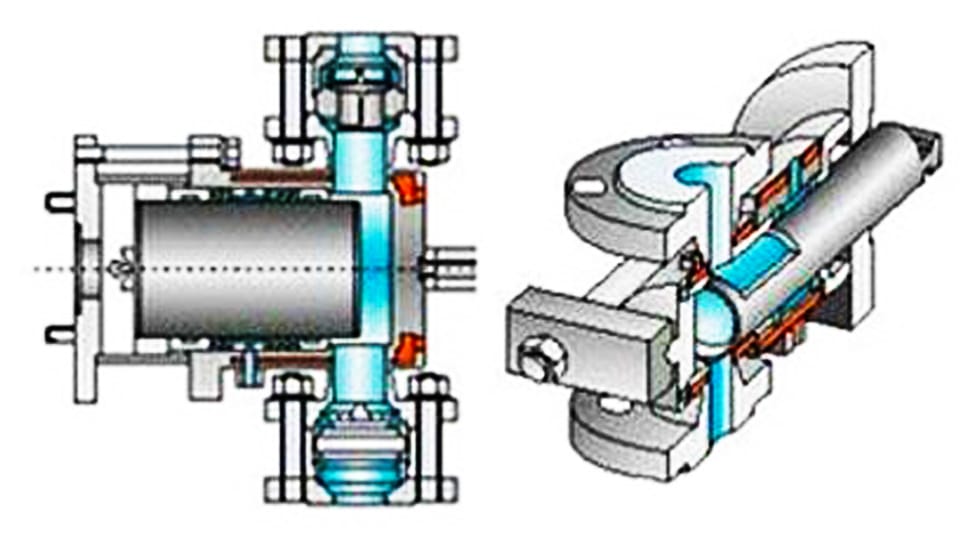

Reciprocating positive displacement pumps work by repeated back and forth motions (strokes) of the piston, plunger or diaphragm (see figure below). These cycles are called reciprocating.

In a piston pump, the first stroke of the piston creates a vacuum that opens the inlet valve, closes the outlet valve and draws fluid into the piston chamber (suction phase). When the piston motion is reversed, the inlet valve, now under pressure, closes and the outlet valve opens, allowing the fluid in the piston chamber to be expelled (compression phase). A bicycle pump is a simple example. Piston pumps can also be double acting, with inlet and outlet valves on either side of the piston. While one side of the piston is in the suction state, the other side is in the compression state. More complex radial versions are often used in industrial applications.

Piston pumps operate in a similar manner. The volume of fluid moved by a piston pump depends on the cylinder volume; in a plunger pump, it depends on the plunger size. The seal around the piston or plunger is important to maintain the pumping action and avoid leakage. In general, the piston pump seal is easier to maintain because it is fixed at the top of the pump cylinder, while the seal around the piston moves up and down repeatedly in the pump chamber.

Diaphragm pumps use a flexible membrane instead of a piston or plunger to move the fluid. By expanding the diaphragm, the volume of the pumping chamber is increased and fluid is drawn into the pump. Compressing the diaphragm reduces the volume and discharges some fluid. Diaphragm pumps have the advantage of a sealing system, making them ideal for pumping hazardous fluids.

The cyclic action of a reciprocating pump creates pulses during discharge, with the fluid accelerating during the compression phase and decelerating during the suction phase. This can cause damaging vibrations in the installation and is often damped or smoothed in some way. Pulsation can also be minimized by using two (or more) pistons, plungers or diaphragms, one in the compression phase and the other in the suction phase.

The repeatable and predictable action of reciprocating pumps makes them ideal for applications requiring precise metering or dosing. By varying the stroke rate or length, it is possible to provide a measured amount of fluid to be pumped.

Rotary displacement pumps

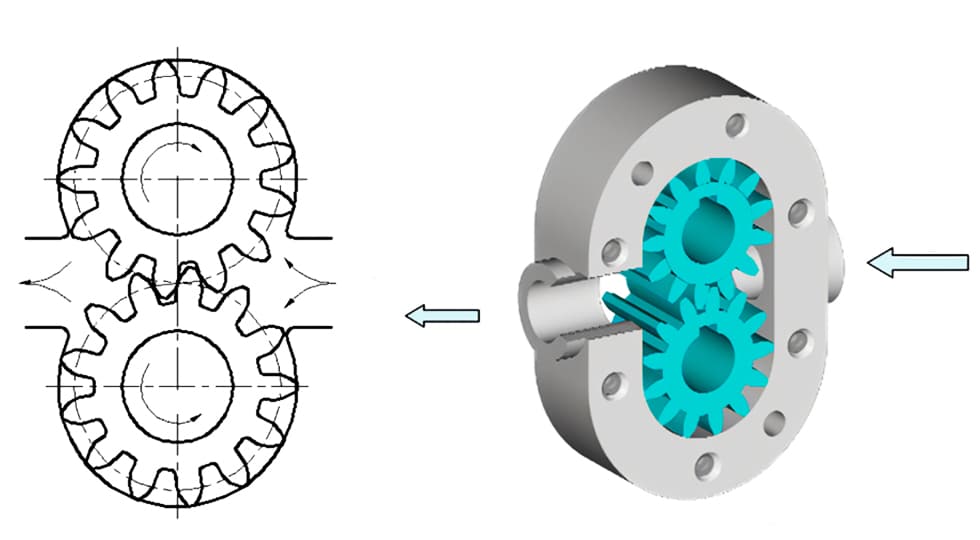

Rotary positive displacement pumps use the action of a rotating gear or gears to transfer fluid rather than the back and forth motion of a reciprocating pump. The rotating element forms a fluid seal with the pump casing and creates suction at the pump inlet. The fluid being drawn into the pump is enclosed within the teeth of its rotating gear or gears and transferred to the discharge port. The simplest example of a rotary displacement pump is a gear pump. Gear pumps come in two basic designs: external and internal (see figure below).

External gear pumps consist of two interlocking gears supported by separate shafts (one or both of these shafts can be driven). The rotation of the gears traps fluid between the teeth, moving it from the inlet to the discharge port around the housing. Because they are interlocked, no fluid is transmitted back through the center between the gears. The tight tolerances between the gears and housing allow the pump to create suction at the inlet and prevent fluid from leaking back out the discharge side. Low viscosity fluids are more likely to leak or “slip”.

Internal gear pumps work on the same principle, but with two interlocking gears of different sizes, one rotating inside the other. The cavity between the two gears is filled with fluid at the inlet and conveyed to the discharge port, where it is discharged by the action of the smaller gear.

Gear pumps require lubrication of the fluid being pumped and are ideal for pumping oil and other high viscosity fluids. For this reason, gear pumps should not be idle. The tight tolerances between the gears and housing mean that these types of pumps are prone to wear when used with abrasive fluids or feeds containing entrained solids.

Two other designs similar to gear pumps are lobe pumps and vane pumps.

In the case of a lobe pump, the rotating element is a cam rather than a gear. The biggest advantage of this design is that the vanes do not come into contact with each other during pumping, thus reducing wear, contamination and fluid shear. A vane pump uses a set of movable vanes (spring loaded, hydraulic or flexible) mounted in an eccentric rotor. The vanes maintain a tight seal with the casing wall and deliver the trapped fluid to the discharge port.

Another class of rotary pumps uses one or more webbed screws to convey fluid along the screw shaft. The basic principle of these pumps is that of the Archimedean screw, a design that has been used for thousands of years in irrigation.

What are the main features and advantages of positive displacementpump?

There are two main families of pumps: positive displacement pumps and centrifugal pumps. Centrifugal pumps can provide higher flow rates and can be used with lower viscosity liquids. In some chemical plants, 90% of the pumps are centrifugal. However, there are many applications where positive displacement pumps are preferred. For example, they can handle higher viscosity fluids and can operate more efficiently at high pressures and relatively low flow rates. They are also more accurate when metering is an important consideration.

What are the limitations of a positive displacement pump?

Displacement pumps are more complex and more difficult to maintain than centrifugal pumps. They also do not produce the high flow characteristics of centrifugal pumps.

Displacement pumps are not as capable of handling low viscosity fluids as centrifugal pumps. To generate suction and reduce slippage and leakage, rotary pumps rely on seals between their rotating elements and the pump casing. The use of low-viscosity fluids can significantly reduce this situation. Similarly, it is more difficult to prevent valve slippage in reciprocating pumps with low-viscosity feeds because of the high pressures generated during the pumping action.

Pulsating discharge is also a characteristic of positive displacement pump designs, especially reciprocating pump designs. Pulsation can cause noise and vibration in the piping system as well as cavitation problems that eventually lead to damage or failure. Pulsation can be reduced by using multiple pump cylinders and pulsation dampers, but this requires careful system design. Centrifugal pumps, on the other hand, produce a smooth, constant flow.

The back and forth motion of a reciprocating pump can also be a source of vibration and noise. Therefore, it is important to build a very strong foundation for this type of pump. Because of the high pressures generated during the pumping cycle, it is also important that the pump or discharge line has some form of pressure relief in the event of a blockage. Centrifugal pumps do not require overpressure protection: in this case, the fluid is simply recirculated.

A feed containing large amounts of abrasive solids can cause excessive wear on components of all types of pumps, especially valves and seals. Although the components of displacement pumps operate at much lower speeds than centrifugal pumps, they are still susceptible to these problems. This is especially true for piston and plunger reciprocating pumps and gear rotary pumps. With this type of feed, a lobe, screw or diaphragm pump may be suitable for more demanding applications.

The following table summarizes the performance of centrifugal and displacement pumps.

| Property | Centrifugal | Positive Displacement |

| Effective viscosity range | Efficiency decreases with increasing viscosity (max. 200 Cp) | Efficiency increases with increasing viscosity |

| Pressure tolerance | Flow varies with changing pressure | Flow insensitive to changing pressure |

| Efficiency decreases at both higher and lower pressures | Efficiency increases with increasing pressure | |

| Priming | Required | Not required |

| Flow (at constant pressure) | Constant | Pulsing |

| Shearing (separation of emulsions, slurries, biologican fluids, food stuffs) | High speed motor damages shear-sensitive mediums | Low internal velocity. Ideal for pumping shear sensitive fluids |

What are the main applications of positive displacement pumps?

Positive displacement pumps are typically used to pump high viscosity fluids such as oils, paints, resins or foods. They are preferred in any application where precise metering or high pressure output is required. Unlike centrifugal pumps, the output of positive displacement pumps is not affected by pressure, so they are also often preferred in any situation where supply is irregular. Most are self-priming.

| Types of positive displacement pump | Application | Features |

| Piston pump | Water – high pressure washing; other low viscosity liquids; oil production; paint spraying | Reciprocating action with piston(s) sealed with o-rings |

| Plunger pump | Reciprocating action with plunger(s) sealed with packing | |

| Diaphragm pump | Used for metering or dispensing; spraying/cleaning, water treatment; paints, oils; corrosive liquids | Sealless, self-priming, low flows and capable of high pressures |

| Gear pump | Pumping high viscosity fluids in petrochemical, chemical and food industries: oil, paints, foodstuffs | Meshed gears provide rotary pumping action |

| Lobe pump | Chemical and food industries; sanitary, pharmaceutical, and biotechnology applications | Low shear and wear. Easy to clean or sterilise |

| Screw pump | Oil production, fuel transfer and injection; irrigation | Fluid moves axially reducing turbulence; capable of high flow rates |

| Vane pump | Low viscosity fluids; automotive transmission systems; fuel loading and transmission; drinks dispensers | Resistant to entrained solids and withstands vane wear. Design allows variable output |

Summary

Positive displacement pumps move fluid by repeatedly closing a fixed volume with the help of seals or valves and moving the fluid mechanically through the system. The pumping action is cyclic and can be driven by a piston, screw, gear, vane, diaphragm or vanes. There are two main types: reciprocating and rotary.

Volumetric pumps are suitable for applications involving high viscosity fluids (e.g. thick oils and slurries), especially at high pressures, for complex feeds (e.g. emulsions, food or biological fluids), and where precise metering is required.