PD series milton roy lmi digital dosing pump is a mechanically-actuated diaphragm pump driven by advanced variable speed technology to provide the most accurate and reliable performance in the industry.

PD series Milton Roy LMI Digital Dosing Pump

LMI’s family of electronic metering pumps offer:

Functions and advantages

Use general power 115-230v, 50/60hz drive platform

• maximum flow up to 7.57l /H(2GPH), maximum pressure up to 30.6bar(450PSI)

• simplified flow control with constant stroke length to maintain calibration within adjustable range. Advanced electronic components with dynamic compensation for temperature and voltage conditions

• FastPrime hydraulic end (standard), can be integrated discharge valve fast easy for perfusion(optional), AutoPrime hydraulic end, specially designed for degassing liquid (please see page 4) on performance specifications

•NEMA 4X/IP 65 enclosure is rugged and suitable for use in the most hostile environments and outdoors

• compact size, efficient use of space in processing applications or OEM configurations

• agency certification – NSF 61 and 50 (in application), ETL, CE

• decades of experience and LMI two-year warranty support

| LMI electromagnetic metering pump |

| Large stroke frequency60spm/100spm

Power: 22W |

|||

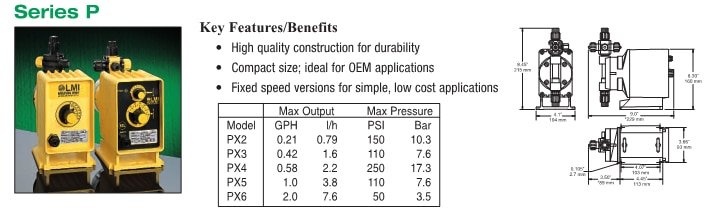

| Specifications and code | Model | Flow(L/h) | Pressure(bar) |

| 0.5 | P026/P126 | 0.01~0.79 | 10.3 |

| 0.9 | P036/P136 | 0.02~1.60 | 7.6 |

| 0.5 | P046/P146/P746-y | 0.02~2.20 | 17.3 |

| 0.9 | P056/P156/P756-y | 0.04~3.8 | 7.6 |

| 1.8 | P066/P166/P766-y | 0.08~7.6 | 3.5 |

| 1.8 | P086/P186/P786-y | 0.12~12.1 | 1.5 |

The electromagnetic drive

Brief introduction:

Flow rate: 0-95 l/h

High pressure: 70 bar

Stroke speed and length are adjustable

Manual/automatic control mode

Programmable control

Main series: P.A, B.C.E

Main applications: all kinds of circulating water treatment applications, reverse osmosis, swimming pool water treatment, waste water treatment, etc

The New PROTEUS Communications Model adds support for Modbus RTU and Profibus (Process Field Bus) DP protocols to facilitate high speed, 2-way communications. This allows plant operators to link devices from different vendors to a central SCADA (Supervisory Control And Data Acquisition) system for control, monitoring, and troubleshooting activities.

PROTEUS metering pumps are mechanically actuated diaphragm pumps driven by advanced variable speed technology to address specific requirements of chemical addition in water treatment. All three configurations of PROTEUS pumps – Manual, Enhanced, and Communications – also address the process control requirements of a wide range of applications including water and wastewater treatment, agricultural, chemical, oil & gas; power generation, pulp & paper, and textile industries.

Whatever your application, the PROTEUS series is ready to outperform and outsmart your most demanding application.

‘HAOSH‘ is a major dosing metering pump brand of Shanghai GL Environmental Technology Co., Ltd. Also as a pump category super market, we supply diaphragm pumps, chemical pumps, water pumps, screw pumps, etc. Since founded in 2007, HAOSH brand has for more than 100 countries of the world’s more than 3000 clients with high quality pumps.