The ARO non-metallic offering consists of polypropylene, acetal and PDVF. Robust construction with thick walled injection, molded fluid casings and cast iron or aluminum center sections to withstand tough industrial applications.

Air Operated Diaphragm ARO Pump

Non-Metallic Models

The ARO non-metallic offering consists of polypropylene, acetal and PDVF. All ARO pumps are available with convoluted diaphragms offering long convoluted lasting life and reduced maintenance.

[MAIN PARAMETER]~Material: Aluminum; Diaphragm Material: Nitrile;

Type: Double diaphragm;

Operation Type: Air-operated;

Inlet/Outlet Port Size/Standard:1 inch (25 mm);

Air Inlet Size: 1/4 inch (6.35 mm)

[Quality Performance ~Maximum Head:275.59FT/84M,

Max Pressure: 120PSI.

Max Temp : 150 ℉.

Top quality glyd ring, a double-acting seal that delivers better performance.

[UNIQUE DESIGN]~Features an externally serviceable air distribution system and all-bolted construction. Modular air valve is stall-free, this low pulsation air valve provides smooth and rapid changeover for increased efficiency and minimizes down time.

[EXCELLENT CONSTRUCTION]~Rugged construction – resists corrosion for reliable performance and long life. Bolted construction is designed for leak-free fluid handling.

[VERSATILE USE]~The diaphragm pump with convenient operating are widely used in various industries, such as petroleum, metallurgy, mining, coating material, printing, paper making, water treatment, automotive etc.

Robust construction with thick walled injection, molded fluid casings and cast iron or aluminum center sections to withstand tough industrial applications.

Efficiency – Motor design delivers optimum air efficiency

Reliability – ARO’s patented ‘Unbalanced’ air valve ensures no-stall operation

Versatility – Multiple porting options for your application needs – Available in Flanged, Threaded, or 3 piece Manifold configurations

Environmentally Sound – Bolted construction for leak-free fluid handling

Serviceability – Easy access to ball checks and fluid caps for maintenance and repairs

Accessories

637161-XX-C Fluid Section Service Kit

637118-C Air Section Service Kit

66073-2 Air Line Connection Kit: contains Piggyback Filter / Regulator, pipe nipple & 5′ section of hose

67078 Flange Connection Kit: converts connection to N.P.T.F. threading configuration

67072 Count Down Batcher

66975 Cycle Counter Kit

Pump Casing Materials

Polypropylene

PVDF (Kynar)

Diaphragm Materials

Viton

PTFE w/ Santoprene backer

Hytrel

Santoprene

Nitrile

Medical Grade Santoprene

Neoprene

E.P.R.

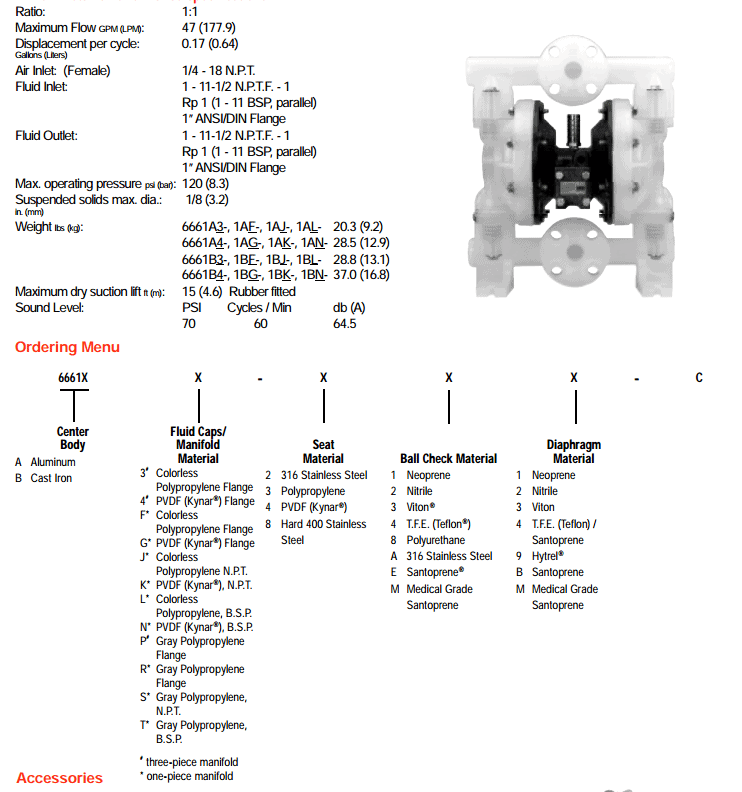

Ratio: 1:1

Maximum Flow: 5.3 g.p.m. (20) l.p.m.

Displacement per cycle: 0.019 Gallons (0.072 Liters)

Air Inlet (Female): 1/4 – 18 PTF SAE Short

Fluid Inlet/Outlet Hybrid: Internal Thread 1/4”NPTF/BSPT

External Thread 3/4” – 14 NPTF/BSPT

Max. operating pressure psi (bar): 125 (8.6)

Suspended solids max. dia. in.(mm): 1/16” (1.66)

Weight lbs (kg):

2.86 (1.3) Polypropylene

3.88 (1.76) PVDF

3.52 (1.60) Acetal

Maximum dry suction lift ft(m) : 15 (4.6)

Sound Level: 70 PSI 60 Cycles/Min 62.3 db(A)

Muffler: Integral, Included

| Product name | Pneumatic diaphragm pump |

| Wetted part | Aluminum |

| Motor body | Aluminum alloy |

| Diaphragm | PTFE |

| Max Flow | 133L/min |

| Air inlet | 1/4”BSPT |

| Gross weight | 11kg |

| Warranty | 1 year(except wearing part) |

What is an aro pump?

ARO started its business in 1930, began selling pumps in the 1950s and was acquired by Ingersoll-Rand in 1990. ARO pump factory has passed ISO9001 and European CE certification, providing high quality products and services.

Ingersoll-rand, ARO pump’s main advantage lies in the key components of pneumatic pump — pneumatic motor, with a number of patents, no dead point, no stall motor, D valve structure and so on, these patents ensure that ARO pneumatic diaphragm pump is in an absolute position in motor technology.

‘HAOSH‘ is a major dosing metering pump brand of Shanghai GL Environmental Technology Co., Ltd. Also as a pump category super market, we supply diaphragm pumps, chemical pumps, water pumps, screw pumps, etc. Since founded in 2007, HAOSH brand has for more than 100 countries of the world’s more than 3000 clients with high quality pumps.