EX: High purity chemical production

EXH: Pumps without internal pressure booster

The EX series of pumps are manufactured from robust polymer materials with high precision CNC machining for high purity chemical production with excellent chemical resistance, improving product quality and environmental protection while reducing maintenance costs.

The EXH series of high pressure pumps offer robust construction for high discharge pressure applications, a specialized diaphragm design, a pneumatic control system for high pressure environments, long life and low maintenance costs, and diaphragm monitoring and spare parts kits to ensure reliability and safety of production operations. This makes it ideal for use in a wide range of applications under high pressure conditions.

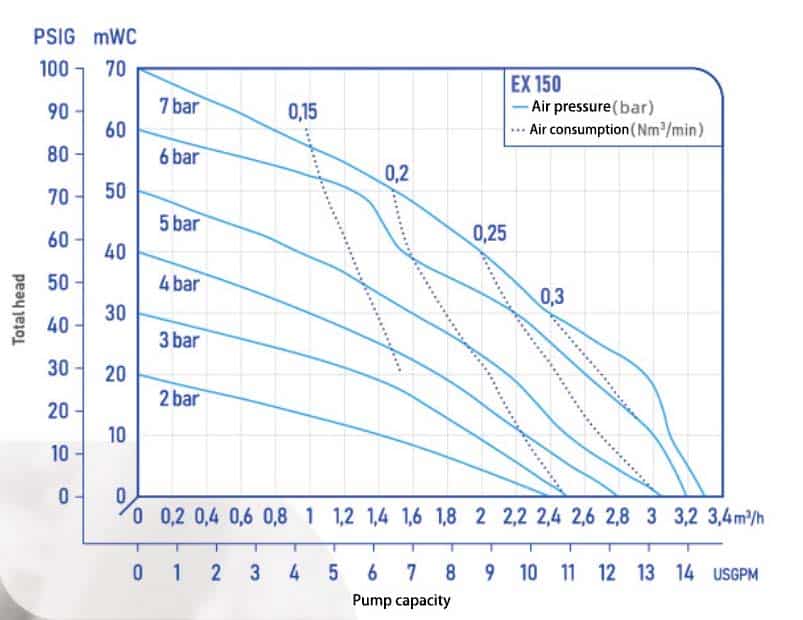

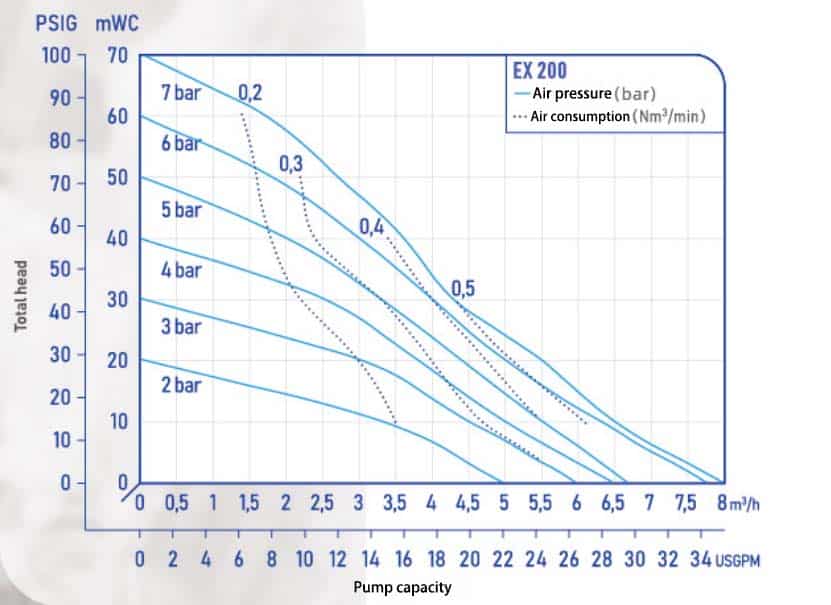

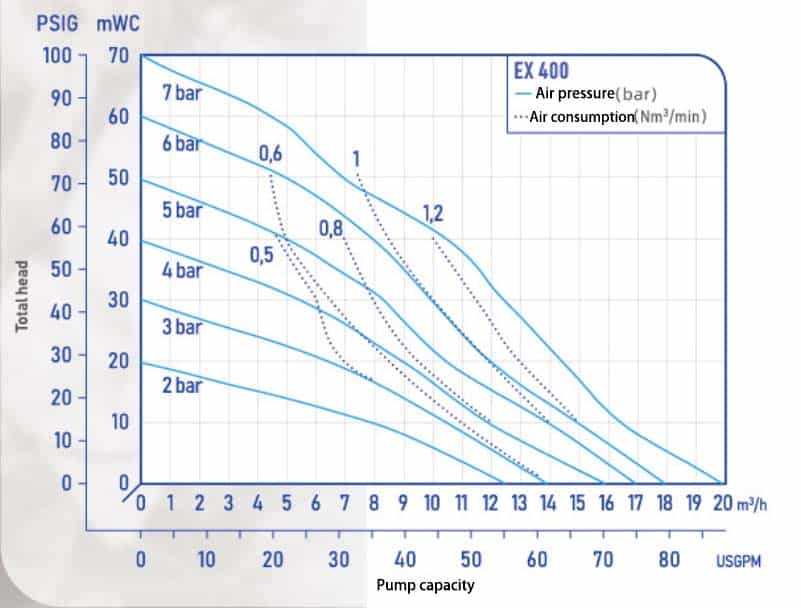

Sizes:EX150(1/2″), EX200(1″), EX400(1.5″)

1. High static weight reduces pump vibration

2. No exposed metal parts

3. Can be used in corrosive environments

4. Easier maintenance

1. PE excellent chemical abrasion and corrosion resistance

2. Generalized chemical corrosion resistance of PTFE

3. Improved durability

1. Good self-priming capability

2. Accommodates ball or cylinder valves of different materials

3. Can detect liquid flow, compatible with a wide range of chemical types

4. Fully sealed

1. No exposed metal parts

2. Connects directly to the pump, no additional piping required

3. Available flange links and threaded links

4. Easy to install, provides almost uniform flow, protects pipework

1. Already installed in the lateral housing

2. Allows drainage without disconnecting from piping

3. Reduces the need for cleaning agents and the amount of solvent used

4. Product recovery of precious liquids

5. Valve can be operated manually or pneumatically

6. Virtually eliminates residue in pumps

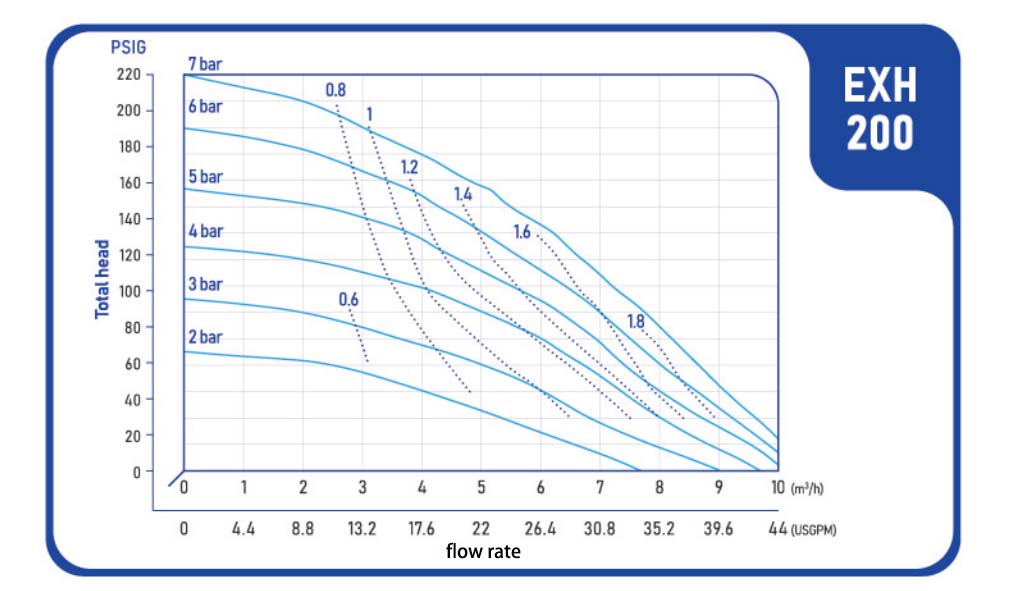

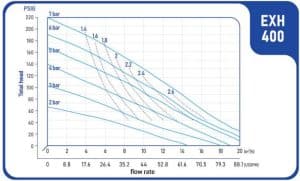

Sizes:EXH200(1″), EXH400(1.5″)

EX:

EXH:

‘HAOSH‘ is a major dosing metering pump brand of Shanghai GL Environmental Technology Co., Ltd. Also as a pump category super market, we supply diaphragm pumps, chemical pumps, water pumps, screw pumps, etc. Since founded in 2007, HAOSH brand has for more than 100 countries of the world’s more than 3000 clients with high quality pumps.