Pneumatic diaphragm pump does not operate or operate very slowly:

1. Ensure that the supply air pressure is at least 0.35bar(5psig) higher than the pressure head and the pressure difference (the difference between the supply air pressure and the liquid discharge pressure) is not less than 0.7bar(10psig).

2. Check whether there is foreign body blockage at the filter membrane of the air inlet (see recommended installation).

3. Check the air leakage (air leakage), which will indicate whether there are bad seals or holes on the air valve, guide shaft and spindle.

4, open the pneumatic diaphragm pump and check whether there are obstacles in the gas path or whether there are objects that hinder the operation of the internal parts.

5. Check whether the check valve is adhered. If the liquid being pumped is not compatible with the pump elastomer, expansion may occur. Replace the check valve and a ball seat with a suitable elastomer. In addition, the ball may become smaller due to wear, which may cause the ball to get stuck in the seat, in which case the ball and seat should be replaced.

6. Check whether the internal pressure plate is damaged, which will prevent the movement of the valve shaft.

7. Unplug the plug from the exhaust end of the guide shaft and check whether the exhaust end of the guide shaft is blocked.

Pneumatic diaphragm pump maintenance pump action, but the flow is small or no liquid flow:

1, check the pneumatic diaphragm pump cavitation phenomenon, reduce the pump speed so that the thick liquid into the liquid cavity.

2. Verify that the height of the lifting liquid under vacuum is not greater than the vapor pressure of the pumped liquid (cavitation phenomenon).

3. Check whether the check valve is adhered. If the liquid being pumped is not compatible with the pump elastomer, expansion may occur. Replace the check valve and a ball seat with a suitable elastomer. In addition, the ball may become smaller due to wear, which may cause the ball to get stuck in the seat, in which case the ball and seat should be replaced.

The air valve of the pneumatic diaphragm pump is frozen: check whether the compressed gas is too wet, and the compressed gas can be processed by installing a dryer or a hot air generator. Alternatively, in some cases condensate filters may be installed to remove moisture from the compressed gas.

There are bubbles at the outlet of pneumatic diaphragm pump:

1. Check whether the diaphragm is broken.

2, check the tightness of the external pressure plate.

3. Check bolt torque and O-ring and seat integrity, especially suction line.

4. Make sure the pipe is connected and sealed.

The product flows from the gas outlet:

1. Check whether the diaphragm is broken.

2, check the sealing of the external pressure plate and the shaft.

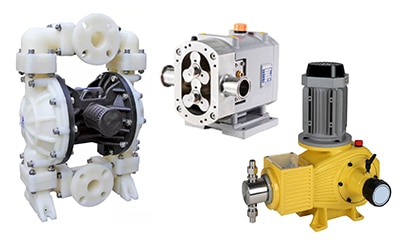

Hot selling pump: T8 wilden pump, T15 wilden pump.

More models of wilden pumps, please contact us.