Why do we need to add chlorine in industrial circulating water? How to monitor the chlorinated disinfection water with a residual chlorine tester?

In the effluent stage of tap water and sewage treatment plants, chlorination and disinfection processes are widely used to kill bacteria and viruses in the water. In the treatment of industrial circulating cooling water, the process of chlorination, sterilization and algae removal is also used, because during the cooling water cycle, due to the evaporation of part of the water, the nutrients in the water are concentrated, and bacteria and other microorganisms will multiply and easily form slime. Dirt, too much slime dirt can cause pipeline blockage and corrosion.

Chlorination disinfection generally refers to the introduction of chlorine gas into the water to kill bacteria and other microorganisms, and bottled chlorine gas is usually used.

Free chlorine-Chlorine produces HClO and ClO- in water, and the sum of HClO and ClO- is called “free chlorine”. Among them, free chlorine has a strong killing effect on bacteria and other microorganisms, and is an effective disinfectant component in free chlorine, so HClO is also called “effective free chlorine”.

Compound chlorine-before the free chlorine has a bactericidal effect, because there are various impurities such as ammonium ions and organic matter in the water, these impurities will first react with the free chlorine and consume a part of the free chlorine. For example, free chlorine will rapidly form monochloramine and dichloramine with ammonium ions in the solution. Over a long period of time, free chlorine will also react with organic compounds (such as proteins and amino acids) to form various organochlorine compounds. Chloramine and organochlorine compounds are called compound chlorine together.

Total chlorine-combined chlorine plus free chlorine is the total amount of chlorine in the solution, called total chlorine. Among these substances, only free chlorine is an effective disinfectant, and compound chlorine has almost no killing ability. Only after the above chlorine consumption needs are met, there will be excess free chlorine to kill bacteria.

Chlorination amount-The amount of chlorine added during chlorination disinfection is called the amount of chlorine added. The amount of chlorine added should include the amount of chlorine required and the amount of residual chlorine. The amount of chlorine required refers to the amount of chlorine required to kill bacteria and oxidize organic matter and reducing substances.

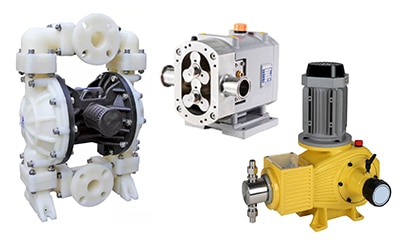

Residual chlorine-refers to the amount of chlorine remaining in the water in order to inhibit the reproduction of residual bacteria in the water, called residual chlorine or residual chlorine. Some people refer to free chlorine as residual chlorine, which is inaccurate. The remaining free chlorine after killing bacteria is residual chlorine. Chlorine dosing pumps are usually used to add chlorination agents to water.

In order to maintain the effect of killing bacteria, the residual chlorine should always be maintained at 0.5-1mg/L in the effluent, and the residual chlorine at the end of the water supply pipe network should also be maintained at 0.05-0.1mg/L. An instrument that measures the remaining free chlorine content in the effluent is called a residual chlorine analyzer.

The online residual chlorine analyzer is mainly used in the following occasions:

① On-line monitoring of residual chlorine content in the effluent of waterworks;

② On-line monitoring of residual chlorine content in the effluent of the sewage treatment plant;

③ Online monitoring of residual chlorine content in circulating cooling water;

④ Online monitoring of residual chlorine content in boiler feed water treatment.

When using disinfected tap water as boiler feed water for desalination, the residual chlorine in the tap water is removed. Because the presence of residual chlorine will destroy the structure of the ion exchange resin, make it weaker and easier to break. Especially when the water is near the water plant, the residual chlorine content in the water is high, and it is more necessary to remove the chlorine. At present, the commonly used dechlorination methods are activated carbon dechlorination method and chemical agent dechlorination method.