Due to people’s activities in the swimming pool, a large amount of dander, hair, sweat, urea and other substances may be left, which will cause the turbidity of the water to rise, the pH value to change, the growth of microorganisms, the proliferation of algae and so on. In view of this, the swimming pool water is treated when it is recycled.

In order to ensure people’s requirements for water transparency, pathological safety and sensory quality, the following process is adopted in consideration of economic factors. That is flocculation-micro-flocculation direct-flow filtration-heating-pH adjustment, residual chlorine adjustment-effluent.

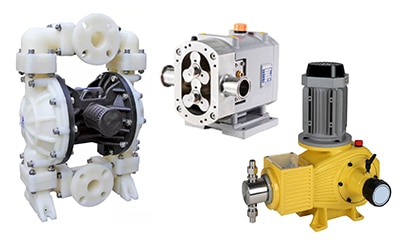

In this process, the dosing of the flocculant adopts the wet dosing of a metering pump in a fixed proportion, that is, the amount of the dosing agent is determined according to the amount of water. The produced alum is subjected to micro-flocculation direct-flow filtration, which can fully remove suspended particles, colloids and other substances that produce turbidity in the water.

The water system is heated by a mixer. The water temperature is controlled by a temperature probe set in the water pipeline to measure the water temperature in real time, and the measured value is compared with the set value to adjust the opening degree of the temperature control valve on the heat medium pipeline.

Due to people’s activities in the water, the PH value of the water is bound to be changed. Too high PH value and too high PH value are harmful to the human body. For this reason, our process controls the PH value between 7.1-7.6. The method of PH value dosing adopts metering pump wet dosing; the adjustment process is to measure the PH value in the water in real time through the sensor on the pipeline, and the value is sent to the secondary meter, and the measured value and the set value are carried out through the secondary meter. In comparison, when the measured value is higher than the set value, the meter will give a signal to the metering pump to reduce the working frequency of the metering pump; when the measured value is lower than the set value, the meter will give a signal to the metering pump to make the metering pump increase Large operating frequency.

In order to achieve the requirement of killing bacteria and viruses, we use sodium hypochlorite for disinfection to ensure that the residual chlorine content in the water is between 0.5-1.0 mg/L. The method of adding the disinfectant is also wet-dosing with a metering pump. The remaining chlorine control adjustment process is to measure the chlorine value in the water in real time through the sensor on the pipeline, and the value is sent to the secondary meter, and the measured value is compared with the set value through the secondary meter. When the measured value is higher than the set value, The meter will give a signal to the metering pump to make the metering pump reduce its working frequency; when the measured value is lower than the set value, the meter will give a signal to the metering pump to make the metering pump increase its working frequency. Go out of the water and return to the swimming pool.

The swimming pool project manager department will provide you with a sanitary, safe, reliable and healthy swimming pool water quality. Welcome to contact us.